Before starting the manufacturing stage, here are some basic technical points.

LEXICON

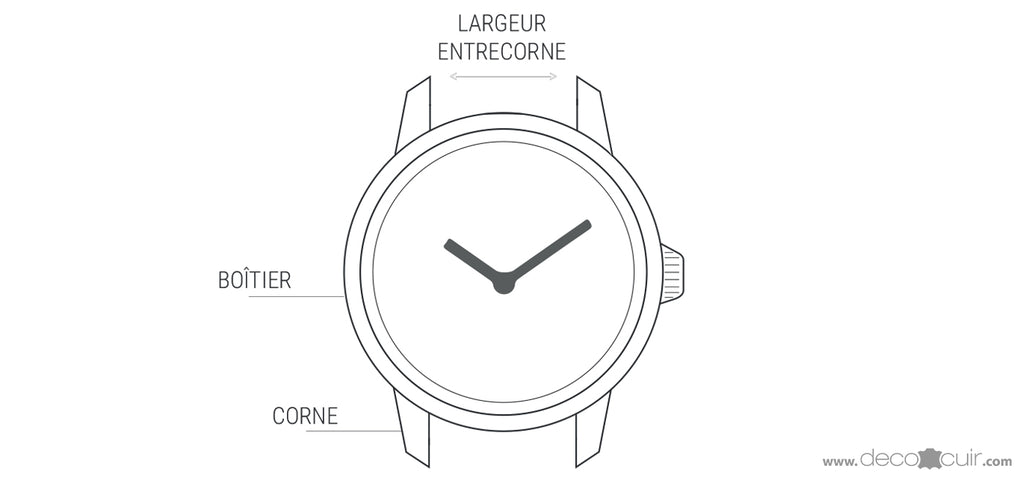

HORNS

The lugs are located on each side of the case and allow the watch strap to be attached using a spring bar.

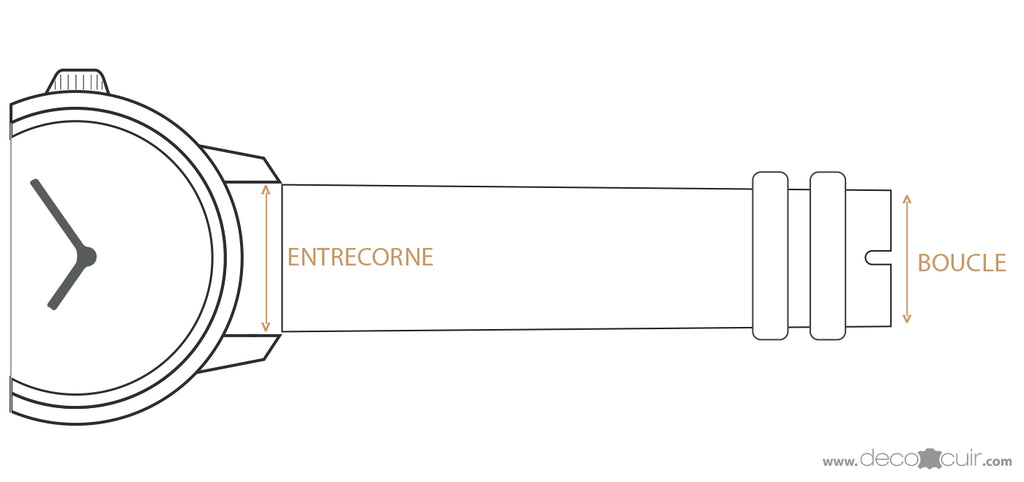

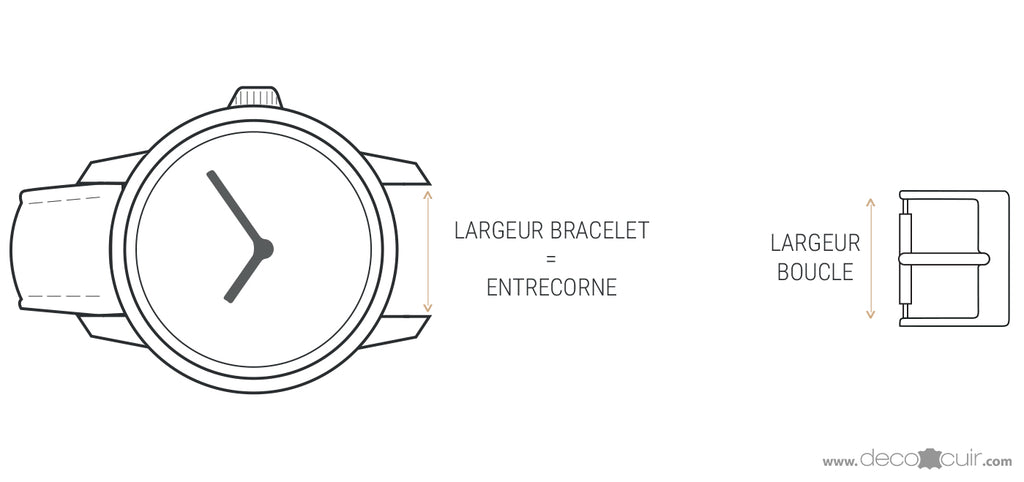

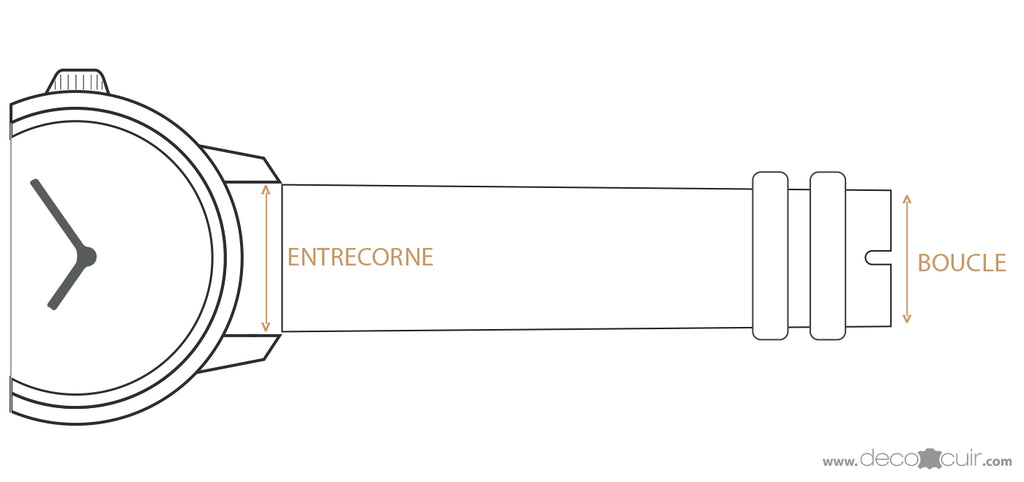

BETWEEN CORNERS

This is the width between the two lugs of the watch case.

SPRING PUMPS OR BARBETS

PUMPS : also called "spring bars" are essential for installing the watch strap to the case.

There are mainly two models:

- The classic spring-loaded pumps/bars are the most commonly used.

- Fast pumps or flash pumps with lugs (compatible with all types of watches) .

There are also other models such as T-bars with rivets, also called "screw pumps".

Ideally, you should use your watch's original spring bars (only if they are standard type) , in which case you can easily find them on specialized websites. If your original watch strap has quick-release spring bars (with tabs), we advise you to buy new ones; otherwise, you risk damaging your leather strap trying to remove them.

For this guide, we primarily used standard spring bars (especially in the main video) . Here's an explanatory video for a watch strap with quick-release spring bars (lug spring bars) .

THE PUMP FLUSH TOOL

Beyond the tools needed for leatherwork, this tool will be indispensable for removing and attaching the pumps to your case.

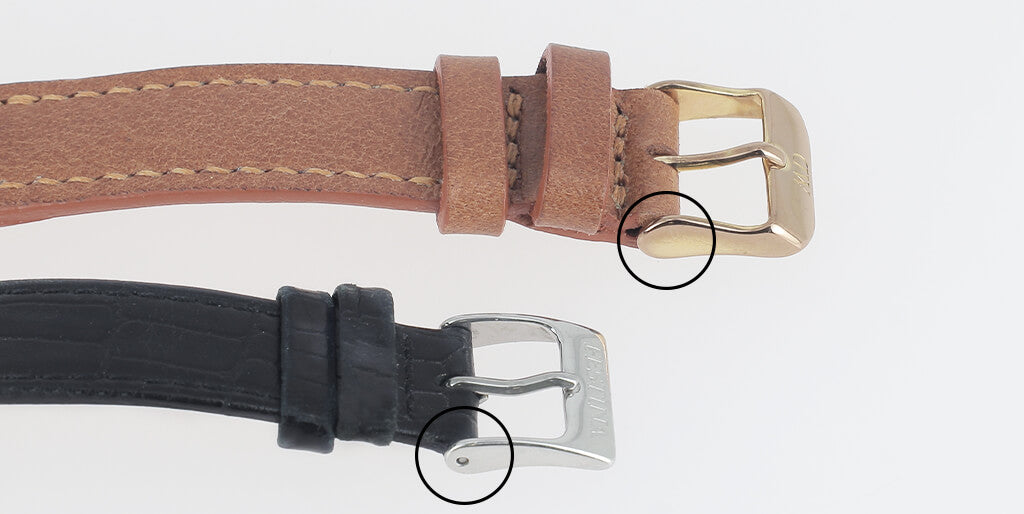

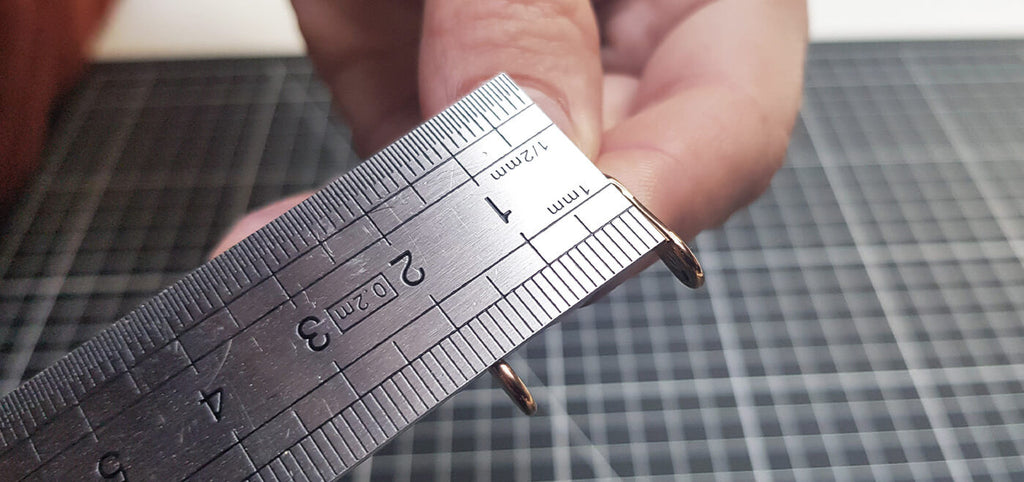

A spring bar tool typically has two different ends: one end with a fork for integrated spring bars and one end with a point for cases with drilled lugs. This tool is also used to remove the tang buckles from your watch straps (watch buckles also have spring bars) .

As previously mentioned, the pump flusher usually has 2 different nozzles for pierced hooves or for unpierced hooves.

The system is the same for watch buckles.

How do I remove the spring bars to change a watch strap?

Important : Always remove the spring bars from the underside of the bracelet in case the spring bar remover slips, thus avoiding scratches on the case or damage to the grain of the leather.

Steps to remove your watch strap:

- Place the open bracelet flat and upside down on a clean surface.

- Depending on the type of horns:

UNPERCORED HORNS

Carefully insert the spring bar tool's fork between the watch strap and the watch case lug. Locate the part of the spring bar where it can be hooked (where there is a raised section) and gently push it inwards. Release the spring bar and repeat the process with the other end of the strap.

PIERCED HORNS

Insert the tip of the spring bar tool into one of the pierced lugs on the case to release the spring bar. Then, gently remove the bracelet with your other hand. Finally, repeat the process with the other end of the bracelet.

The same procedure applies when you want to put the strap back on the case. You only need to make sure that both sides of the spring bar are locked (pull slightly on the strap to check) .

Watch buckles

Watch buckles are generally tang buckles with a spring bar (spring) that can be removed to easily insert the buckle onto your watch strap. The spring bars on the buckles are released in the same way as those on the watch strap: from either the pierced or unpierced side.

How to change a broken watch strap buckle?

Just as when removing the bracelet from the case, we advise you to do this step on the reverse side of the watch ( in order to avoid damaging the grain of the leather in the event of any slippage) .

You will need a replacement watch strap buckle (see above) and a spring bar tool. To determine the required buckle width, measure the strap width at the old buckle, not at the lug width: some straps may be slightly narrower at the buckle (2 mm less) .

Now that the basics have been reviewed, let's move on to making a watch strap.

What size watch strap should I choose?

We will guide you on choosing the right width and length to ensure your watch strap fits your wrist size.

Important : we do not recommend taking measurements from one of your old watch straps which, over time, may have been deformed/shrunk ( heat, humidity, perspiration… ).

The first step is to measure the inside distance between the lugs to determine the required width of the watch strap.

The standard widths of watch straps are: 16 mm - 18 mm - 20 mm and 22 mm.

The lug width, which corresponds to the width of your watch strap, will determine the total length needed for the strap. Note: if the original strap is too small, you will need to adjust the total length (refer to your wrist measurement). Please refer to our table below, which shows the standard sizes.

A closer look at the different watch strap sizes

| Bracelet width or lug dimension | Commercial size | Bracelet lengths | Wrist circumference |

| 16 mm | S | Long strand: 105 mm Short strand: 65 mm Total length: 170 mm |

< 16.5 cm |

| 18 mm | M | Long strand: 115 mm Short strand: 75 mm Total length: 190 mm |

16.5 to 18.5 cm |

| 20 mm | L | Long strand: 120 mm Short strand: 80 mm Total length: 200 mm |

18.5 to 20.5 cm |

| 22 mm | XL | Long strand: 130 mm Short strand: 90 mm Total length: 220 mm |

> 20.5 cm |

*Please note that the lengths indicated correspond to the lengths of the strands after sewing and do not include the length of the watch loop. The table is provided for guidance only.

Standard bracelets are approximately 20 cm long (size L). Generally, a man's wrist measures 15 to 19 cm while a woman's wrist measures 14 to 18 cm .

What are short strand and long strand?

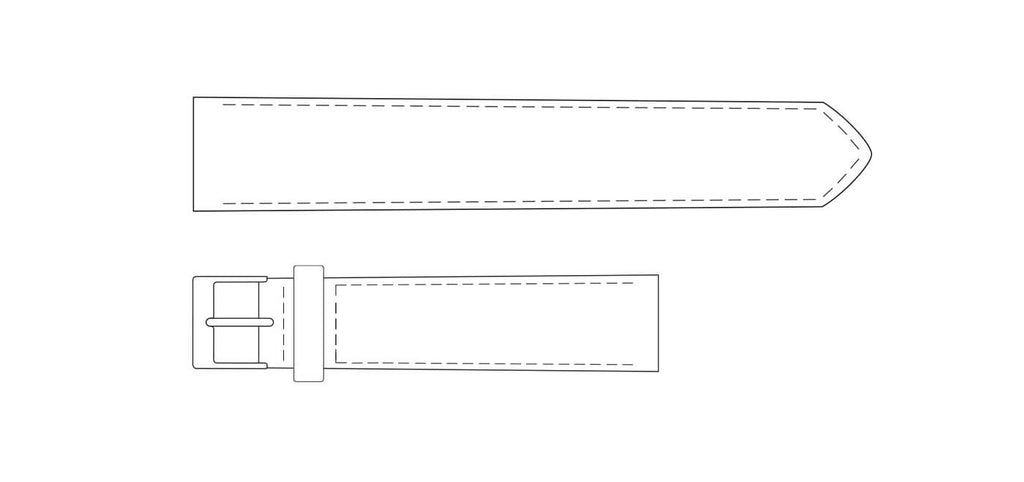

The length of the bracelet is the sum of the short strand (also called loop strand) and the long strand (also called hole strand).

To make it easy to put on the watch, the short end is at the top of the case and the long end is at the bottom of the case.

It is possible that the width at the buckle is 2 mm less than that of the lug width.

Example for a size L : the width at the lug width is 20 mm and the width at the buckle is 18 mm.

Watch straps are usually marked with sizes 20/20 or 20/18…

On our pattern, we tried to offer several variations of the standard sizes (18/16, 18/18, 20/20...) .

SEE THE LEATHER DECORATING PATTERN

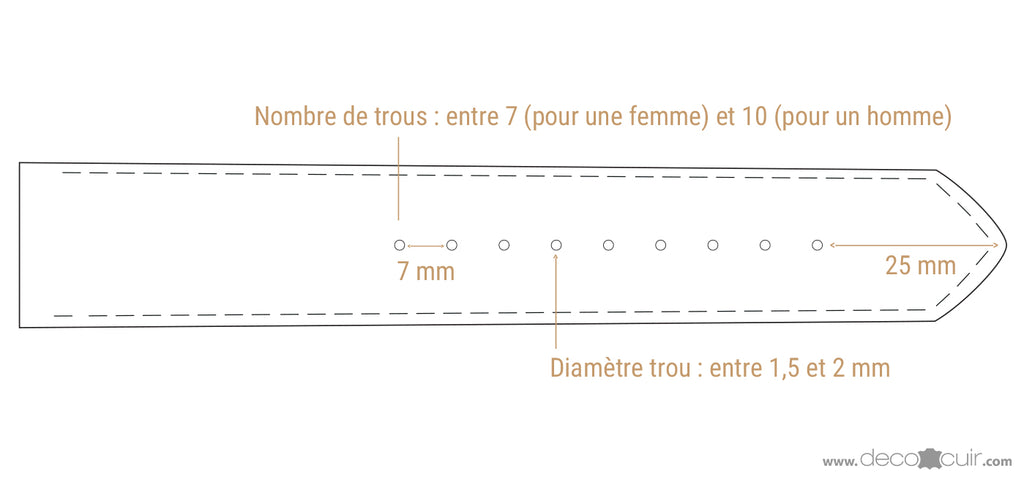

How many holes are there on the long strand?

Generally there is:

- 7 holes on a women's watch strap

- 9 to 10 holes on a men's watch strap

The center of the first hole is located 2.5 cm from the end of the watch strap ( where there is an ogive, trapezoidal, or round end ), except for straps with a 2 mm difference between the lug width and the buckle width. In this case, the first hole is generally located 2 cm from the end.

What is the diameter of the holes in the watch strap?

Just as with the loop on the short strand, the diameter of the holes on the long strand is equal to the width of the buckle's prong.

The diameter of a hole on a watch strap is on average 1.5 to 2 mm.

The spacing between each hole is 7 mm (center to center).

A tool that can help you make watch strap holes:

To make a binding

On the short end, a notch must be made to accommodate the watch buckle's prong. The width of the oblong hole is determined by the width of the prong. Its length is approximately 1 cm .

How do you make the watch strap loops?

There are usually two loops on the short end . The first is secured by stitching on each side (the bracelet stitching and the stitching at the loop, about 5 mm from the edge) , while the second is free. It is essential to secure one of the loops in the stitching to prevent the loose loop from coming off.

The width of a loop is on average 5 mm, its length is equal to 4 times the total thickness of the leather plus 2 times the width.

For example, if our watch strap is 2 mm thick and 16 mm wide: (4 x 2) + (2 x 16) = 40 mm

|

|

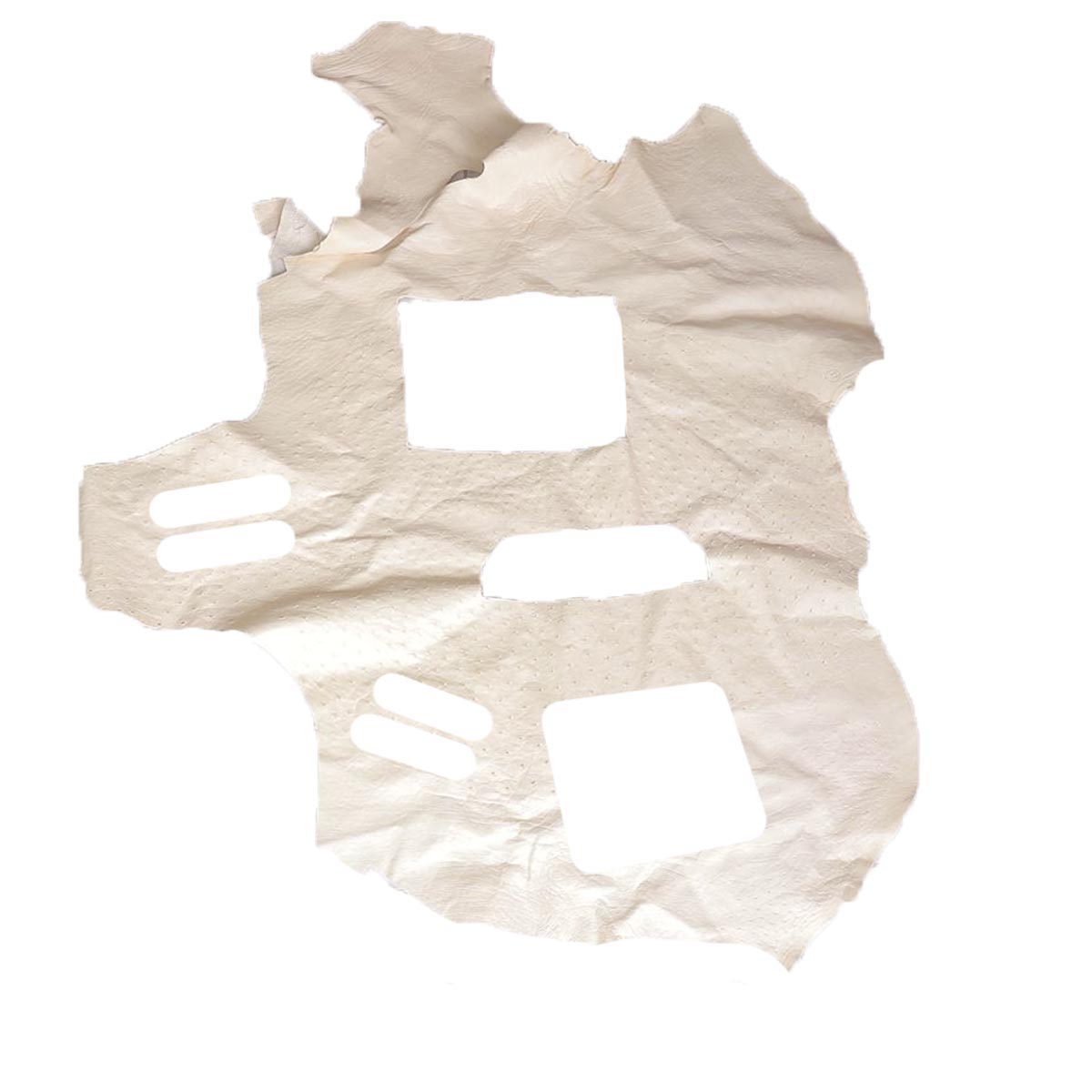

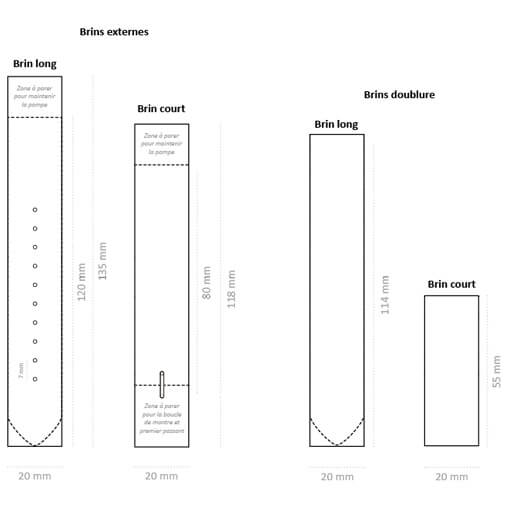

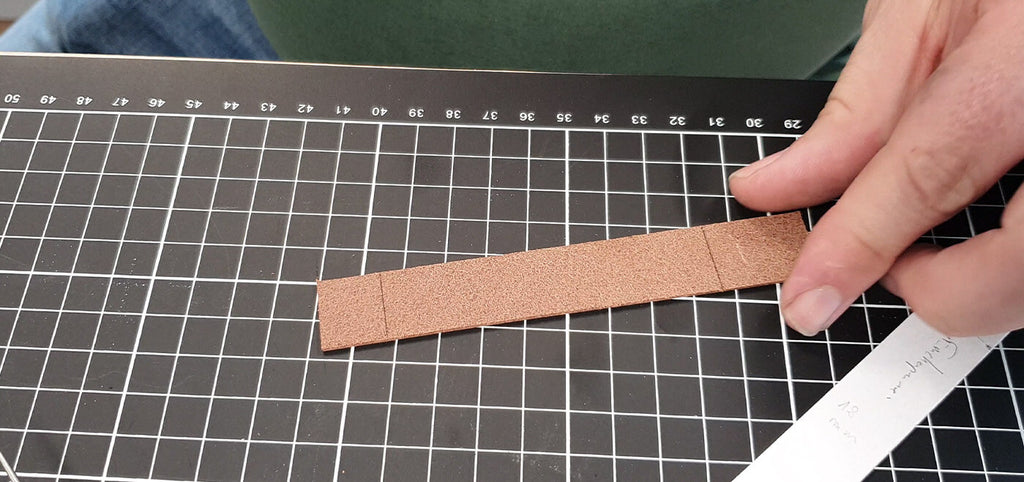

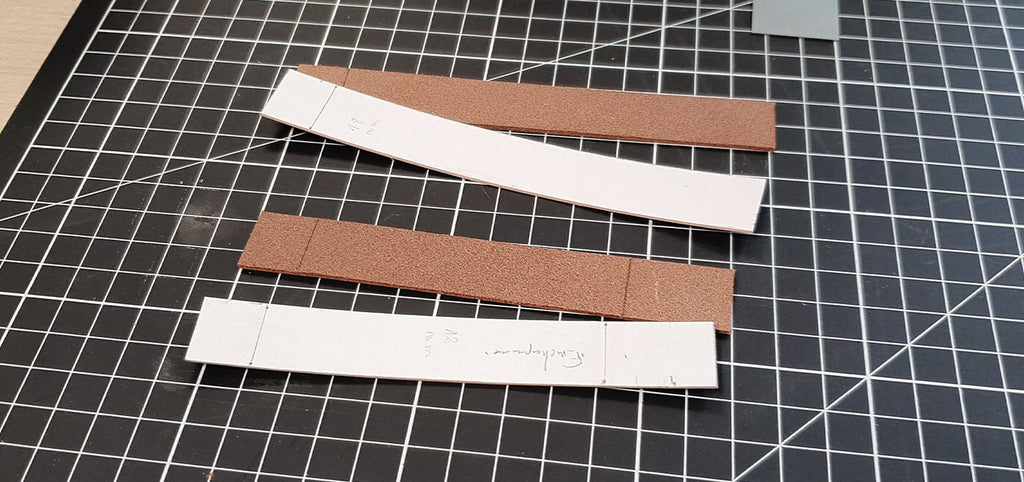

Zoom in on the cutting of the long and short strands on the outer side and lining

In the next step we will discuss the choice of leather for the outer strands and lining (animal, thickness…) .

We invite you to download our free pattern now, which offers the 4 standard watch strap sizes.

SEE THE LEATHER DECORATING PATTERN

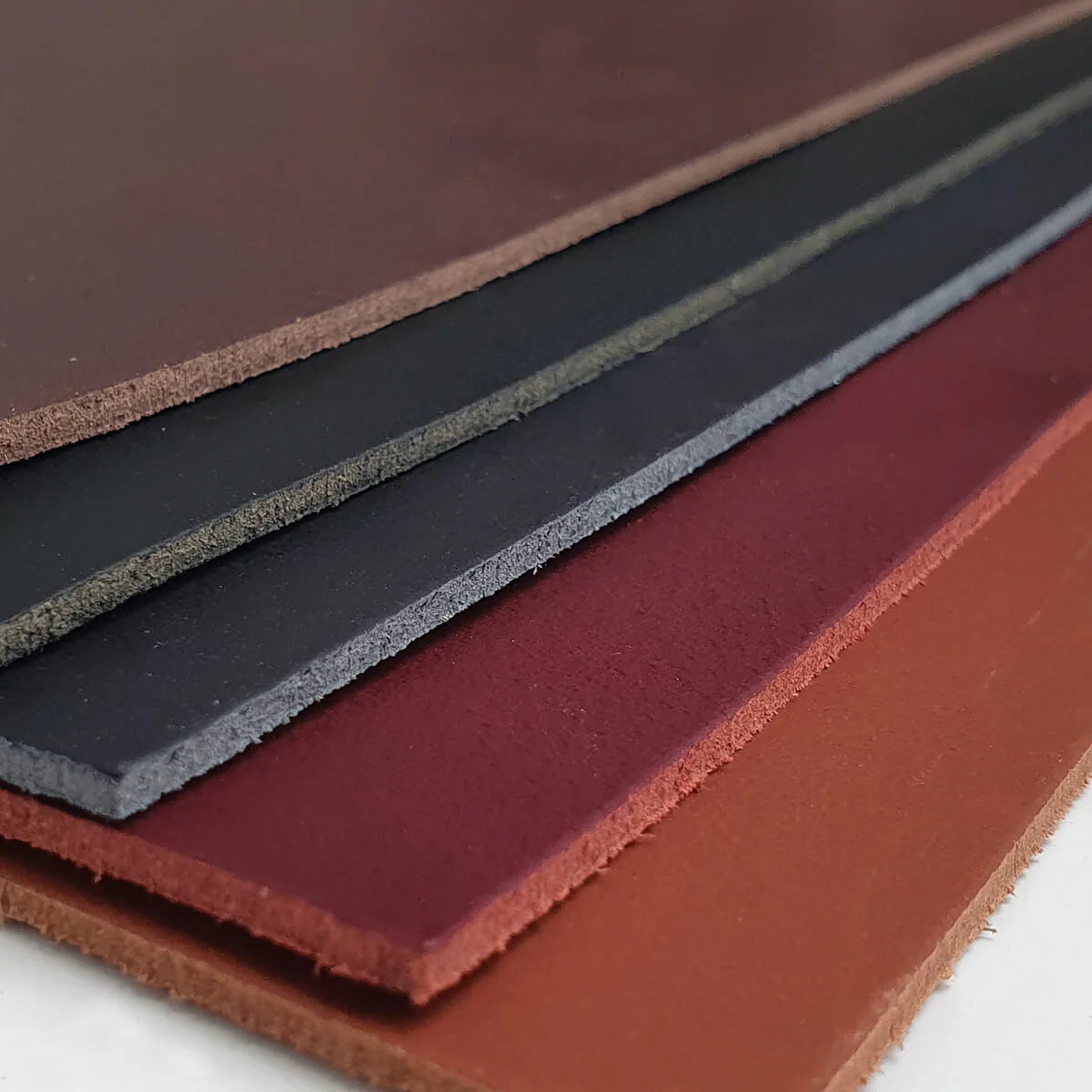

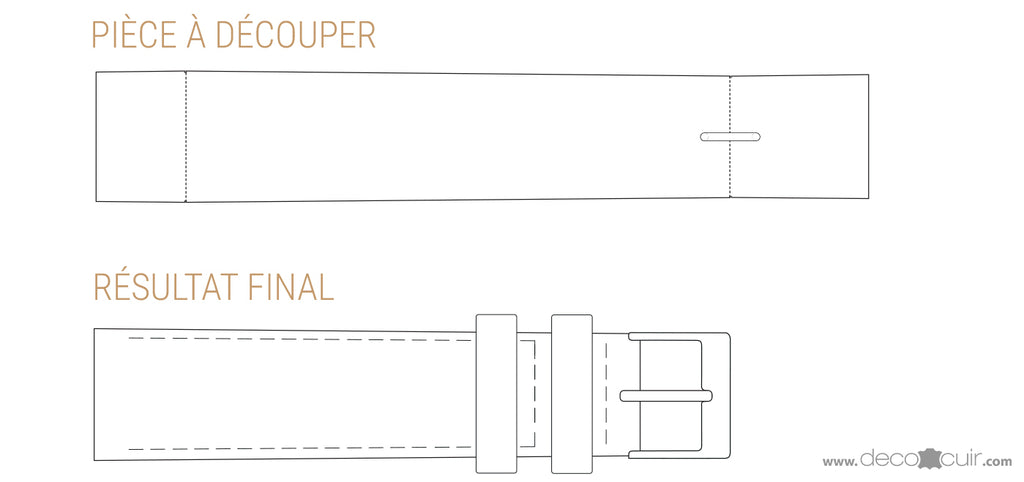

To make a watch strap, you need to cut 4 pieces: 2 outer strands and 2 lining strands. All dimensions are given on our pattern.

EXAMPLE OF CUTTING FOR SIZE L 20/20:

The dimensions are given according to our assembly method. We remind you that there are several methods and that everyone should adapt the information provided (no one has absolute truth).

To help you better understand why there are areas to trim, here is a photo of the result after sewing.

CHOICE OF LEATHER

What type of leather should one choose to make a watch strap?

Classic watch straps are generally made from vegetable or mineral tanned calfskin/cowhide leather (for the outer strands the leather does not necessarily need to be vegetable tanned) .

We invite you to consult the guide below to learn more about the difference between vegetable-tanned and mineral-tanned leather.

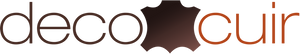

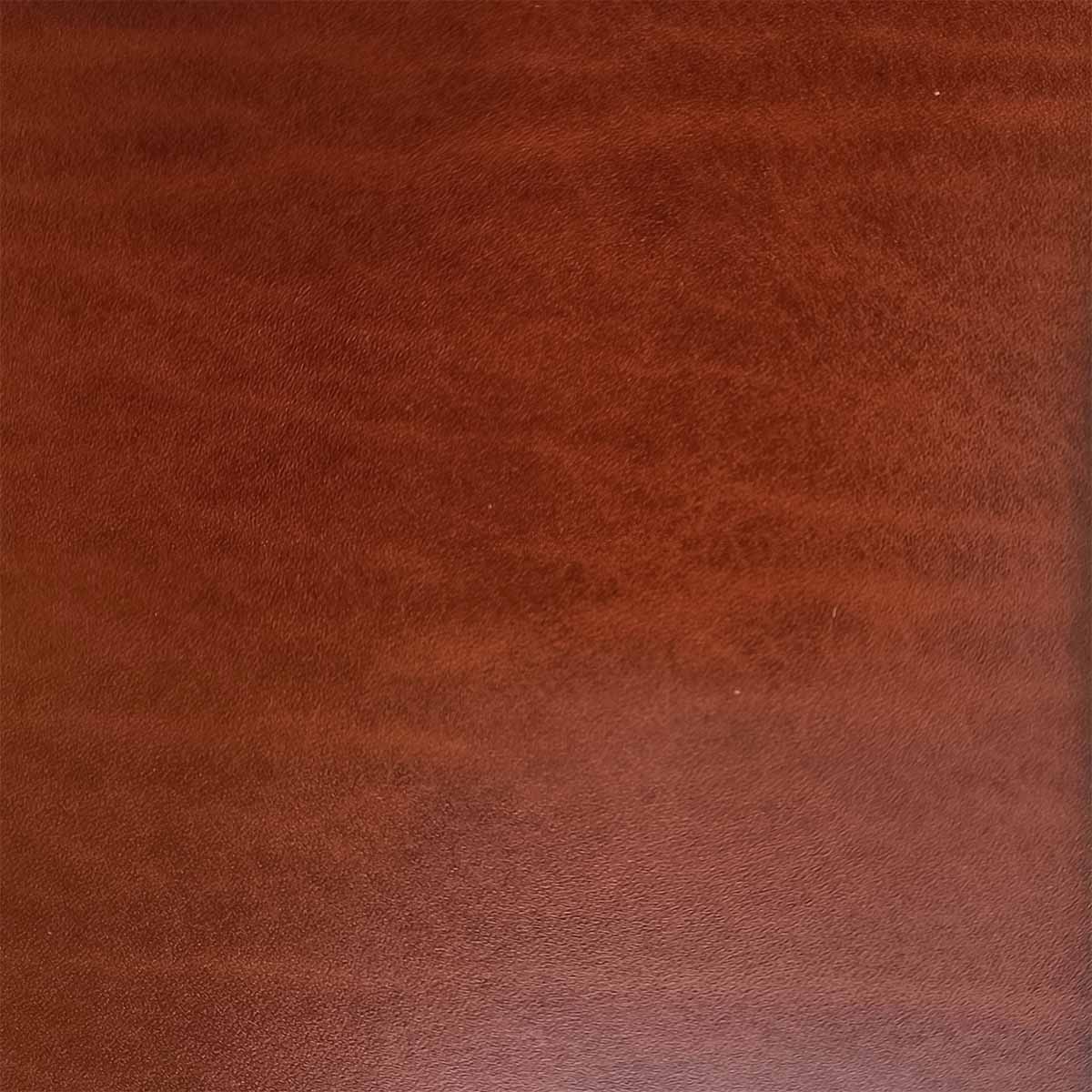

Here is a selection of vegetable-tanned bovine leathers. We particularly love our range of butt leathers, which are perfectly suited to this process (approximately 1.6 mm thick) :

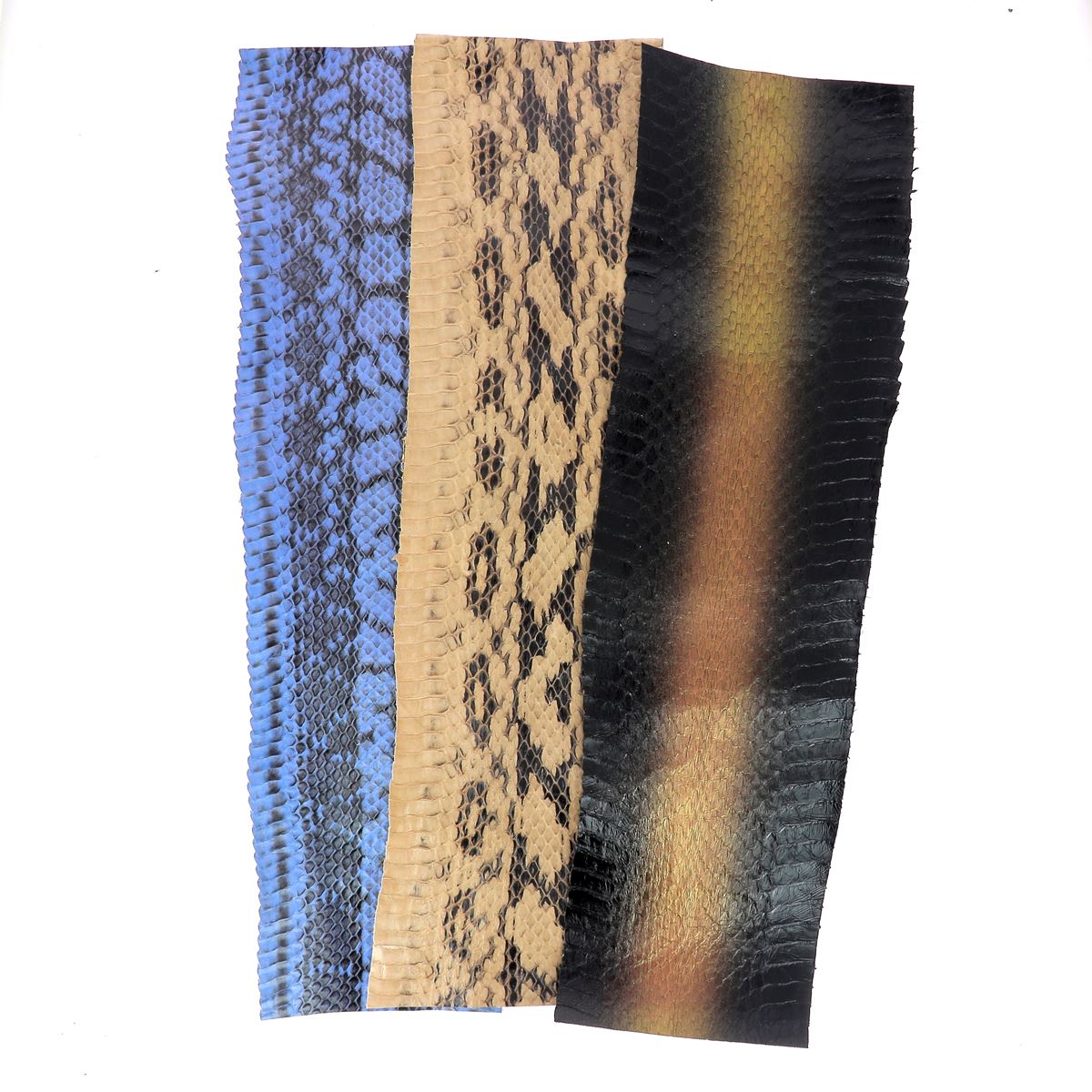

If you wish to give your creation a more luxurious feel, you can choose reptile leather (alligator or crocodile) , snake leather (boa, python, etc.) , fish leather (shark, stingray, etc.) , or ostrich leather. Note that the sale and import of most of these leathers are regulated (CITES).

For this type of leather, which is generally thin, we recommend reinforcing it with vegetable-tanned leather 1 to 1.2 mm thick (see the video a little further down) .

Here is a selection of leathers for sale on our website:

|

|

|

|

What thickness of leather should I choose to make a watch strap?

Generally, a watch strap with a flat structure has a total thickness of approximately 2.5 mm . The thickness can increase to 4/5 mm if you choose a domed structure (we will discuss this further below) .

If your outer strand leather is between 1.5 and 2 mm thick, we recommend selecting a 0.5 mm thick vegetable-tanned lining leather.

If your outer strand leather is less than 1.5 mm thick, we recommend choosing a 1 mm thick vegetable-tanned lining leather.

If you choose a thin and delicate leather (like exotic leathers, for example), you'll need to reinforce it. Feel free to watch the video below for more information. Learn more about this technique.

What type of leather should I choose for the lining strands of the watch strap?

The lining leathers must be hypoallergenic, meaning they must be vegetable-tanned to avoid any risk of allergic reaction. We recommend selecting vegetable-tanned leather 0.5 to 1 mm thick. The leather may appear "white" at first, but it will develop a patina and color over time (it will tan).

It is possible to apply a thin layer of natural gum (tragacanth, arabic or tokonole) to the underside of the watch strap to protect it (a minimum) from perspiration.

For the choice of glue, we recommend a solvent-free, water-based glue .

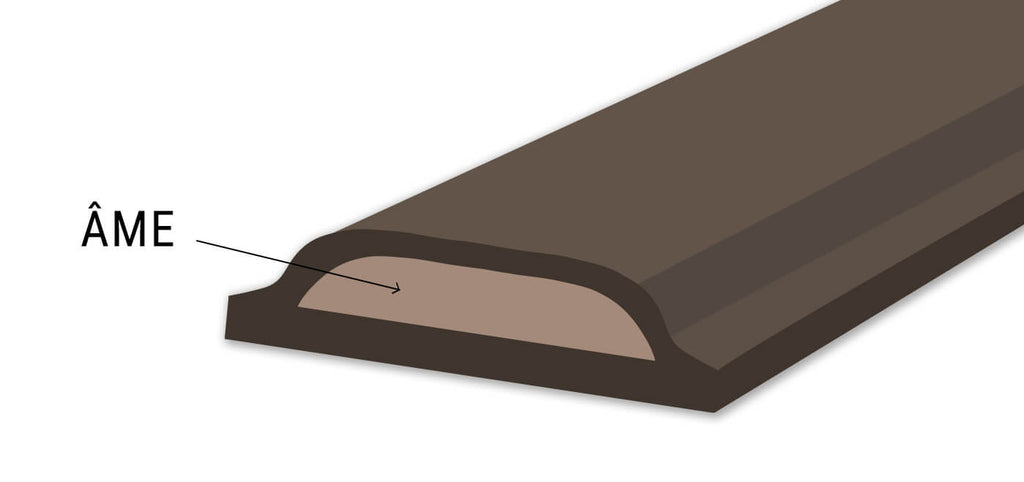

Is it possible to give the bracelet a domed effect?

There are two bracelet structures: either a flat structure or a domed structure. In this guide, we will only look at the flat structure.

To discover and learn more about the curved structure, we invite you to register for our training course which takes place at our premises in Campbon.

To leave you wanting more: the curved shape is generally made with a core. That is to say, a natural vegetable-tanned leather of approximately 1.6 to 1.9 mm thick which is trimmed and glued between the outer strand (whose width is extended by a few millimeters) and the lining strand.

Note that the domed structure does not occur along the entire length of the strands.

- On the short strand, it stops at the level of the loop seam.

- On the long strand, it stops 5 mm from the first hole for the watch buckle.

To give your bracelet a domed effect, mastering leather trimming is essential. Don't hesitate to consult our comprehensive guide on this subject.

|

|

We recommend watching the "Atelier SANG BLEU" video to learn more about domed watch straps here:

What are the steps involved in making a watch strap?

A closer look at saddle stitching

It is not possible to sew a watch strap by machine; the stitching would be impossible at the level of the loops.

Consult the guide on saddle stitching leather before starting to make the watch strap.

Video

1. Detach the old strap from the watch case

Using a spring bar tool, detach the bracelet from the watch case. Also detach the buckle from the watch bracelet. You can keep the same buckle or choose to replace it (we sell them on our website).

2. Determine the bracelet size

Measure the lug width and then the width of the buckle to choose the correct size. The buckle width is also 18 mm. Therefore, you will need to refer to a size 18/18 bracelet.

3. Cut out the pattern pieces

Cut out the pattern pieces, selecting the bracelet size that corresponds to the lug width and buckle width (measured in the previous step). Then glue them onto Texon or thin cardboard to stiffen the templates.

If the watch strap you want to remake is too small or much too large for you, we recommend adjusting the "standard dimensions" of our patterns. As a reminder, you can download the pattern here:

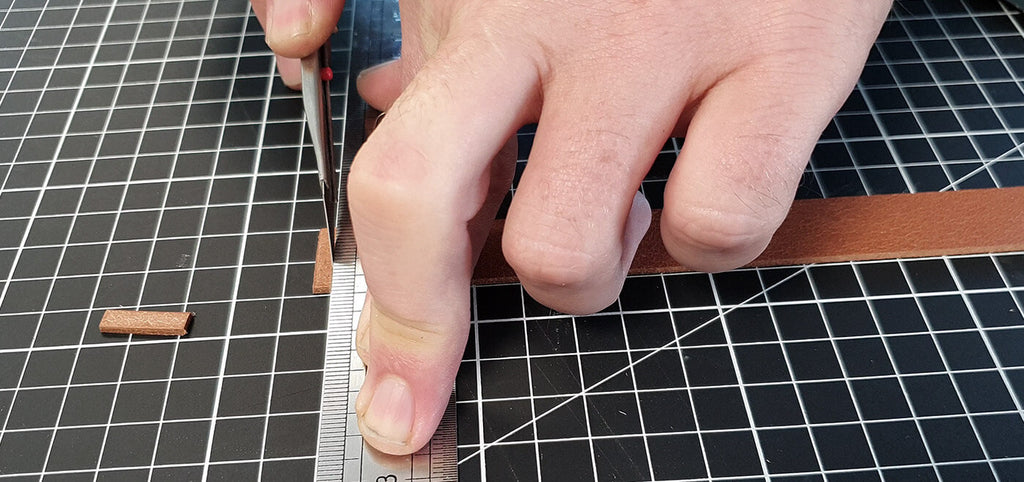

4. Cut the leather

Cut the two outer strands with a craft knife, using the templates as a guide. Refer to the "Choosing the Leather" section in our guide. Then, make a clean trim on each end.

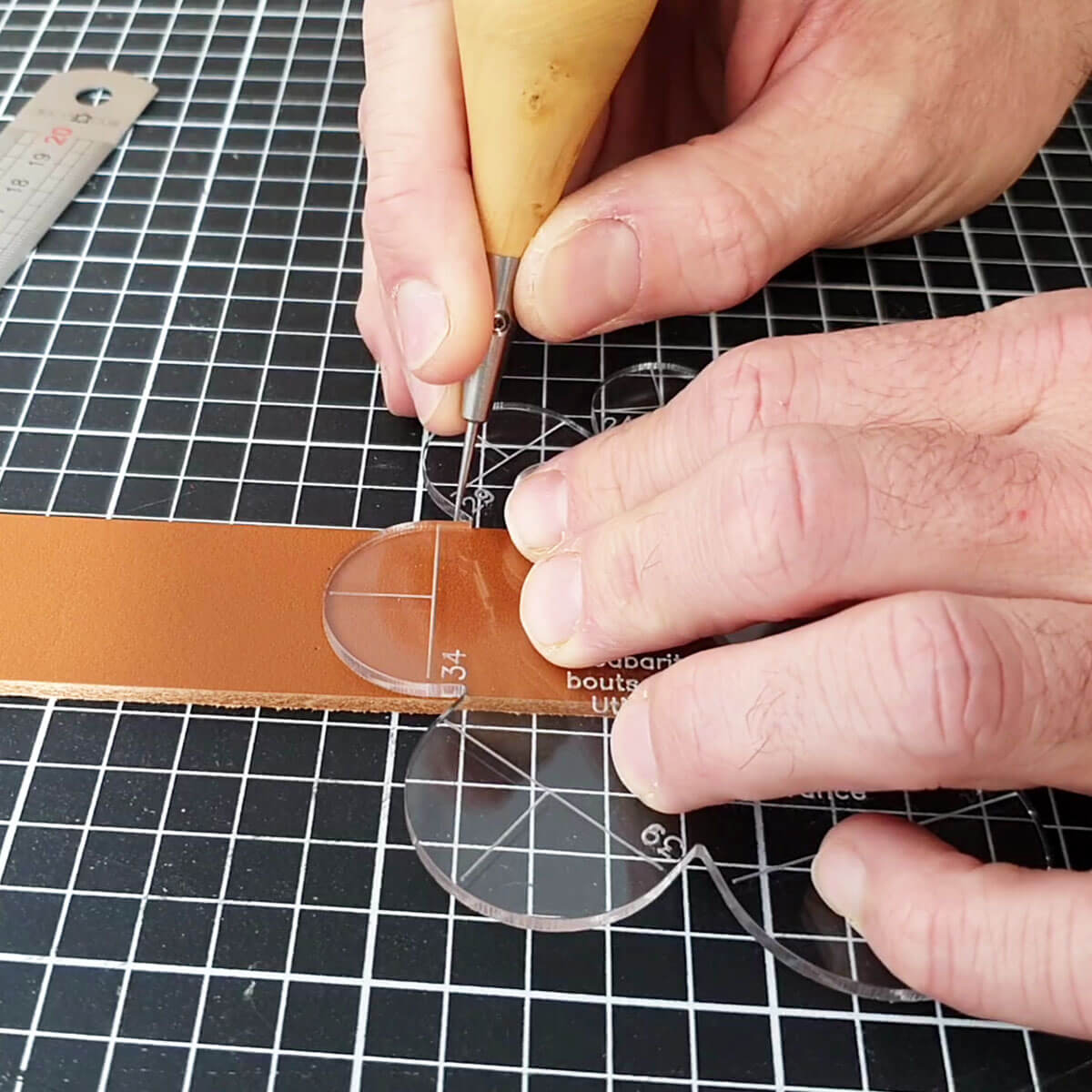

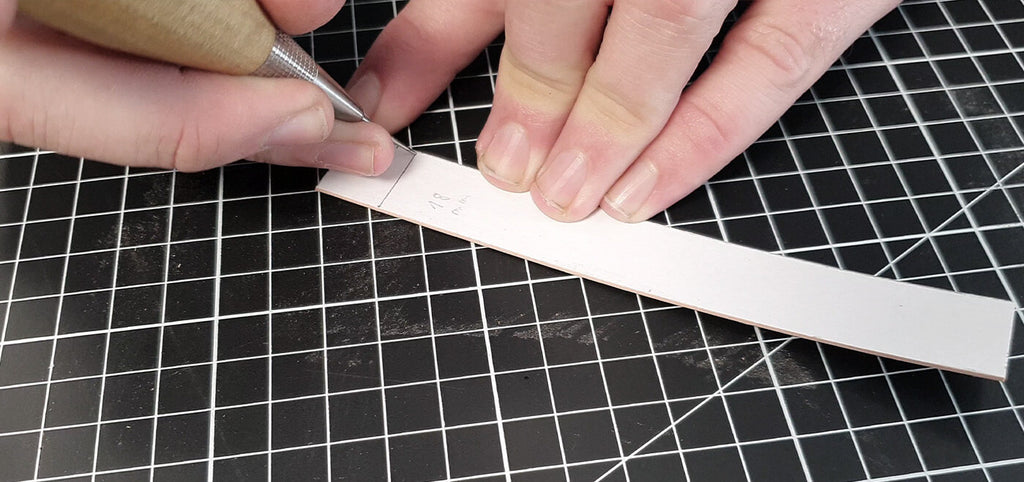

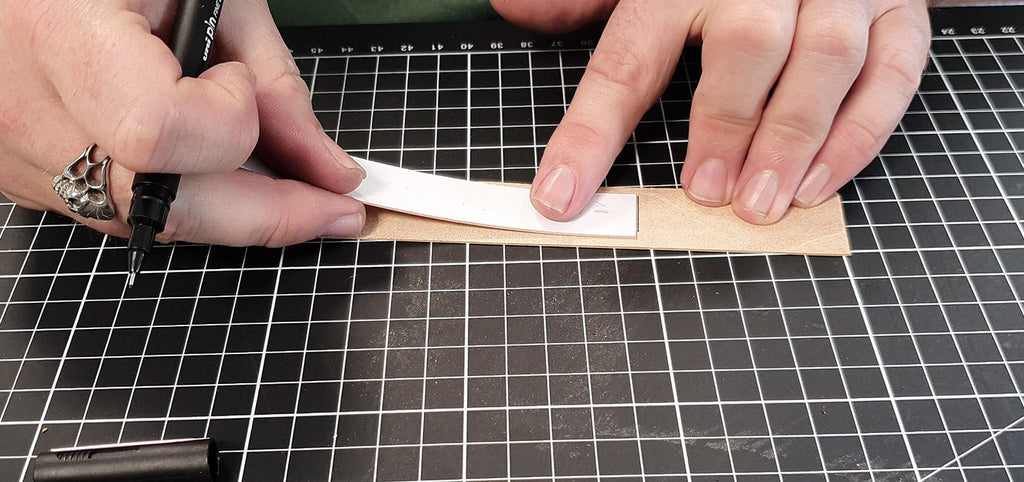

Using a round awl, make a mark on each side of the dotted lines on the pattern (areas to be trimmed and watch buckle attachment area).

Then transfer these markings to the outer strands (flesh side of the leather).

5. Cut out the lining

For cutting the lining strands, we recommend cutting a strip at least 2 cm wider than the templates. Ideally, overcut after gluing (for a neater result).

6. Trim the ends of the outer strands

Make a new mark (in cm) equal to the distance between the end and the fold line. This mark will indicate the area to be trimmed with the knife. The goal is to have the same thickness along the entire length of the cord when the end(s) are folded (for pumps or watch buckles).

Trim all the edges indicated on the pattern. Be careful not to remove too much material.

Then apply tear-resistant tape ( 6 or 8 mm wide ) to the center of the outer strands to reinforce the bracelet and prevent the leather from stretching. Be careful not to apply it to the fold areas.

7. Trim, glue and overcut the lining.

Lightly trim both ends of the short (lining) strand and only the end at the pump for the long (lining) strand to avoid creating bulk. Remember to check the length of the short lining strand on the pattern to adjust the length before trimming (the width will be trimmed after gluing).

Next, make marks on the flesh side of the short strand to determine the gluing area. One mark 14 mm from the fold line at the cuff and another mark 10 mm from the fold area for the pump.

Next, glue the long and short lining strands together. We recommend using a water-based leather glue (since the bracelet will be in contact with the skin). Be careful not to get any glue in the fold areas.

To glue the lining strand to the long strand, we recommend using a "boating" technique: pull on the lining leather to give it a curved shape. Do not do this for the short strand.

Smooth and flatten with a pressure roller.

To finish this step, trim the lining after gluing.

8. Make the chapure and work the passers-by

Position the template on the long strand and mark the location of the headband.

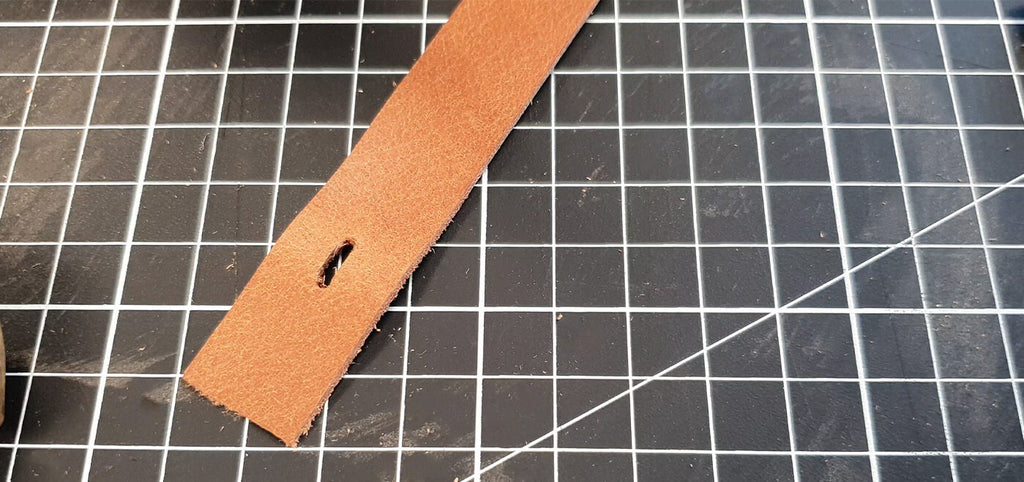

Make the recess for the passage of the watch buckle's tang using a round punch (diameter of the width of the buckle's tang) and a cutter or a straight cutting knife.

Work the spine with a finishing eraser (e.g., tragacanth or tokonole). We do not recommend using an edge finish for this area, as it is too prone to rubbing. Then, use a pair of pliers (with leather tips) to crease the fold.

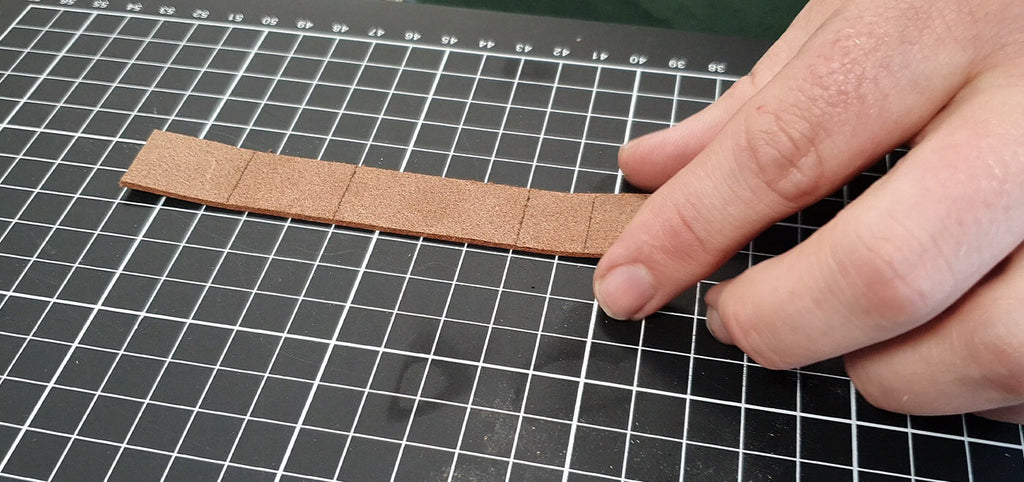

Cut a 5mm wide strip of leather for the 2 loops of the bracelet.

As a reminder, the total length of the loop is equal to 4 times the thickness of the leather plus 2 times the width.

The movable loop will be sewn edge to edge. The second loop will be trimmed and only glued because it will be sandwiched between two seams.

Next, work the edges of the passers-by with an edge finish.

Wait until the slices are dry and sew the movable loop.

Before passing the loop (non-movable) over the long strand, scratch the grain of the lining leather that will be glued (to facilitate the adhesion of the glue) .

Next, glue the ends together. At the pump locations, use a needle to mark the fold.

On the short end, pass the watch buckle's prong through the slot.

The watch buckles are also equipped with a pump (so they can be easily removed/replaced).

Then pass the loop (non-mobile) over the short strand and proceed with gluing.

Use a smoothing tool to flatten the glue and mark the stitching lines (parallel to the loop).

9. Work on the end of the watch strap

Mark the center of the bracelet and use a template to define the shape of the end of your bracelet: ogive, circle, trapezoid, ellipse...

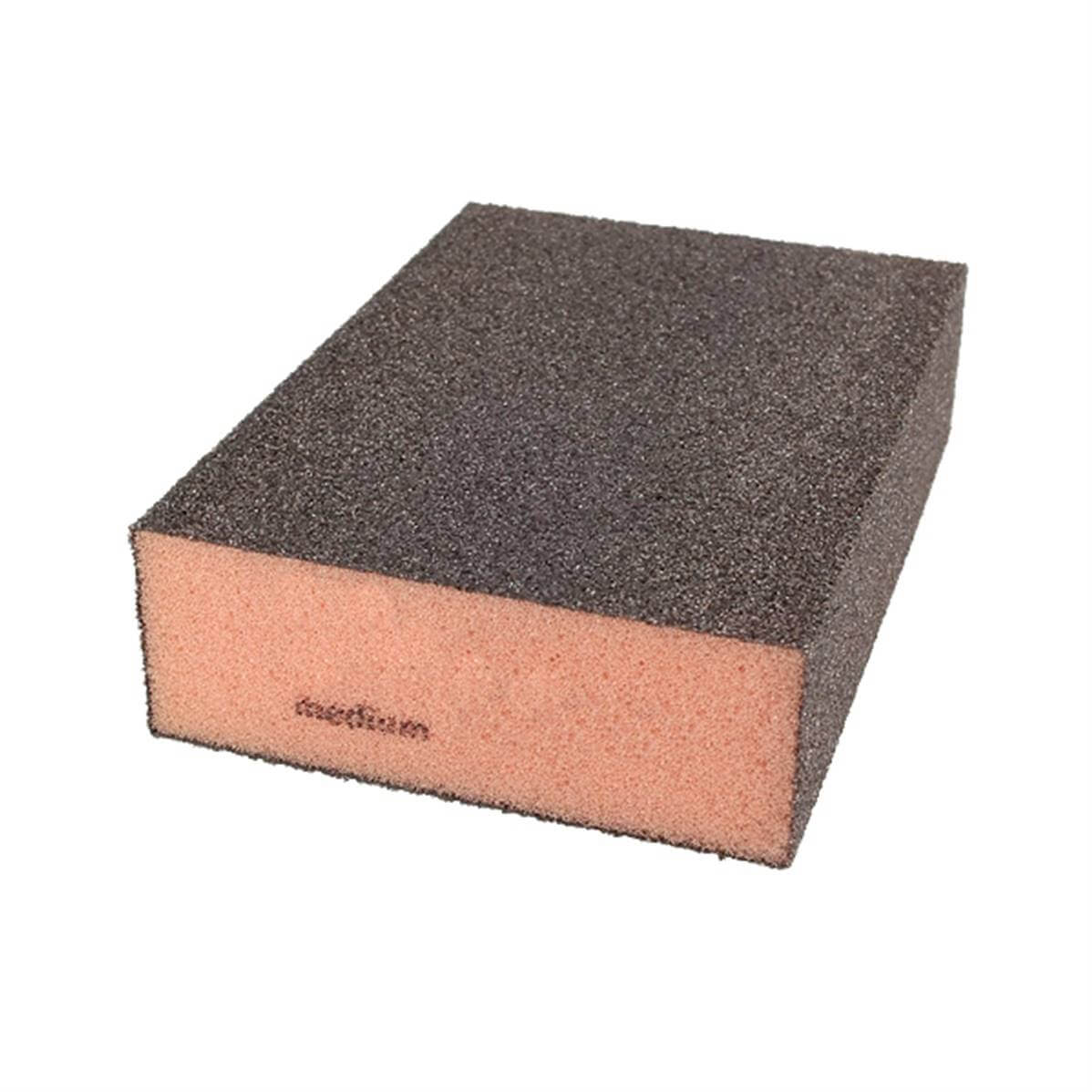

Finish the cut by sanding the edges with an abrasive sponge. Then bevel the two sides of the bracelet.

10. Draw the sewing lines and mark the points

Below is an overview of the sewing lines to be drawn.

Draw the seam line using a dry-point compass 3 mm from the edge.

Then mark the stitching points (do not pierce) with a pricking iron.

11. Saddle stitch

Sew the long and short strands together using a saddle stitch. For the thread, we recommend a diameter between 0.35 and 0.45 mm.

Don't forget to hammer the seams.

12. Work the edges of the bracelet and condition the leather

Check the width of the watch strap before finishing the edges, as the leather may have shifted.

Sand the edges and apply up to 3 coats of finish (sanding between each coat). Do not work the edges at the horns (to avoid creating raised areas). Wax the edges to give them a glossy finish.

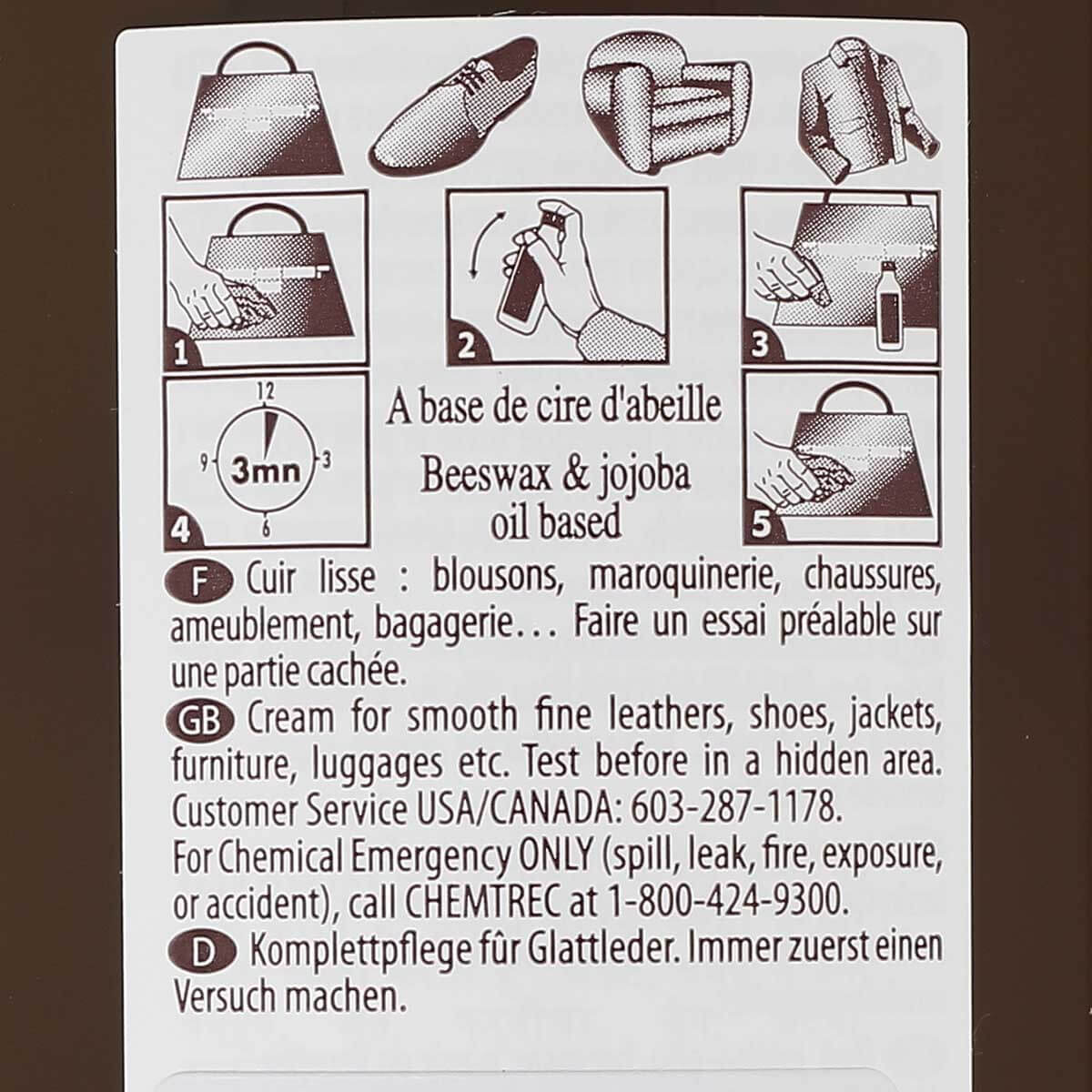

Nourish the leather with neatsfoot oil.

Optional: protect the lining side of the watch strap with a finishing rubber (here Tokonole).

13. Attach the bracelet to the case and make the holes in the long end

Pass the movable loop through and reattach the case to the bracelet.

Using the template, mark the position of the holes (7 to 10 holes) on the long strand. Then drill the holes: the diameter should be equal to the width of the barb. Remember: the spacing is 7 mm center to center.

A tool that can help you make watch strap holes:

The watch strap is finished!

WATCH STRAP MAINTENANCE OVER TIME

How do I tighten a watch strap?

How can I tell if my watch strap is the right size?

To check if your watch is the right size, you should only be able to fit your little finger between the clasp and your wrist. If the strap is much looser, it's not the right size.

How to care for or clean a leather watch strap?

To keep your leather watch straps looking their best for as long as possible, proper care is essential. We recommend storing them in their case or stacking them in a drawer in your wardrobe. This will also prevent scratches on your watch case. When maintaining the case, be mindful of your movements and avoid any impacts. After a while, you can have the case professionally polished at a workshop to minimize scratches and micro-scratches.

To take it a step further, make your own leather watch case

Make a leather pouch to protect and store your watches.

We offer several different sizes to store 1, 2 or 3 watches.

Free tutorial and pattern here:

How to nourish and shine/revive a watch strap?

Here are a few tips to help you keep your watch strap in good condition for as long as possible:

- Avoid contact with water, moisture, perfume, body creams, and prolonged contact with UV/sunlight.

- Change your watch or bracelet regularly to alternate and ensure the longevity of your accessory.

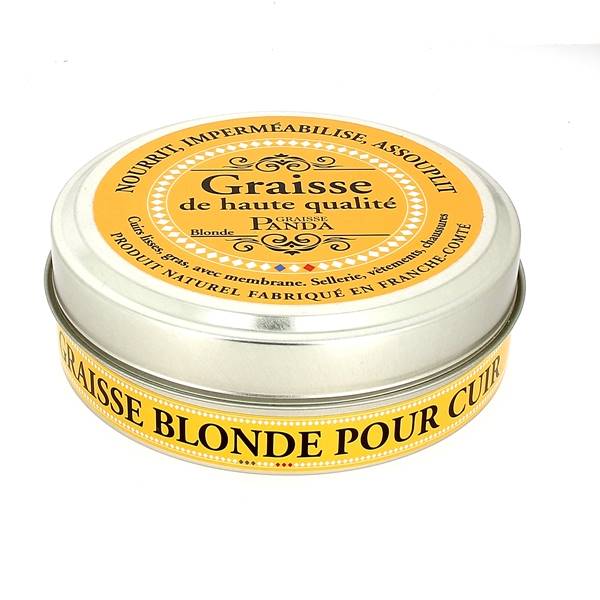

- Use a soft cotton cloth to remove dust and dirt from the case and your strap. When the leather begins to look dull, apply a drop of leather conditioner (e.g., Saphir Universal Cream or a leather grease) to your cloth and gently rub the cloth to nourish the leather (be careful not to use too much). We do not recommend using this cream on all types of leather, and we do not recommend using water or glycerin soap on your leather (unless it is smooth, mineral-tanned cowhide).

- Do not overuse cleaning

Is it possible to change a metal or silicone watch strap to a leather watch strap?

Yes, it is perfectly possible to change a silicone or metal watch strap to a leather one. The only requirement is that your watch strap must be attached to the case using spring bars.

How do I repair the damaged edges of my bracelet?

- Detach the bracelet from the case (to avoid damaging it and to make the job easier).

- Sand the edges with an abrasive sponge (always in the same direction).

- Work all the slices, even those that are not damaged.

- Apply 1 to 2 coats of edge finish, sanding between each coat.

- Rub in beeswax and polish with a cloth.

- You can apply a coat to all sides of your bracelet.

To conclude this guide, a question that some may be asking: which wrist should you wear your watch on?

Traditionally, a watch is worn on the opposite wrist to the dominant hand. For example, right-handed people will wear the watch on their left side: this will reduce the risk of damaging the case (the hand that is less used) and will avoid any inconvenience (e.g., spilling your glass of water to check the time 😉).

This guide interests you and you would like to improve your skills, particularly by learning the technique of the curved structure?

Register for our training course: "Workshop - Making an alligator leather watch strap". The training takes place at our premises in Campbon, Loire-Atlantique.

|

|

You have finished your leather watch strap

|

|

|

|