Sewing choices

There are several methods for sewing a leather wallet:

- Hand-stitched using the saddle stitch

This method allows for a very precise result and is ideal for this type of project. The saddle stitch is particularly appreciated by leather enthusiasts because it is the strongest and most durable stitch.

- Hand-sewn with simplified stitching (with holes)

Simplified hand sewing involves punching the stitching holes using a round punch. This technique, which uses straight stitches, is perfect for beginners because it's easier to do while still looking neat.

SEE THE HOLESTYLE SEWING GUIDE

- To the industrial machine

For those who prefer machine sewing, it is recommended to use an industrial sewing machine, especially with vegetable-tanned leather. This method is the fastest, but you must pay attention to the thickness of the leather and the machine's capacity to handle it.

If industrial machine sewing is chosen for vegetable-tanned leather , the final stitch will need to be done by hand. This last stitch is difficult to achieve even with an industrial machine due to the thickness and rigidity of the leather.

Also note that machine sewing can mark vegetable-tanned leather.

Leather selection

To make this wallet, it is recommended to choose a leather that is both semi-soft and semi-firm, or a firm leather. There are two main types of tanning: vegetable and mineral.

You will also need two different thicknesses of leather:

- A thickness between 0.8 mm and 1 mm.

- A second, thinner one (mainly used for linings) , of about 0.5 mm.

Deco Cuir offers pieces of split leather, perfect for this type of project.

Our selection : In this tutorial, we have selected the Satinlys leather range For example, in mineral tanning, Satinlys leather is ideal for this project because it offers a good balance between suppleness and firmness. We used 0.5 mm thick pieces of leather for some parts and 0.8 mm thick pieces for others.

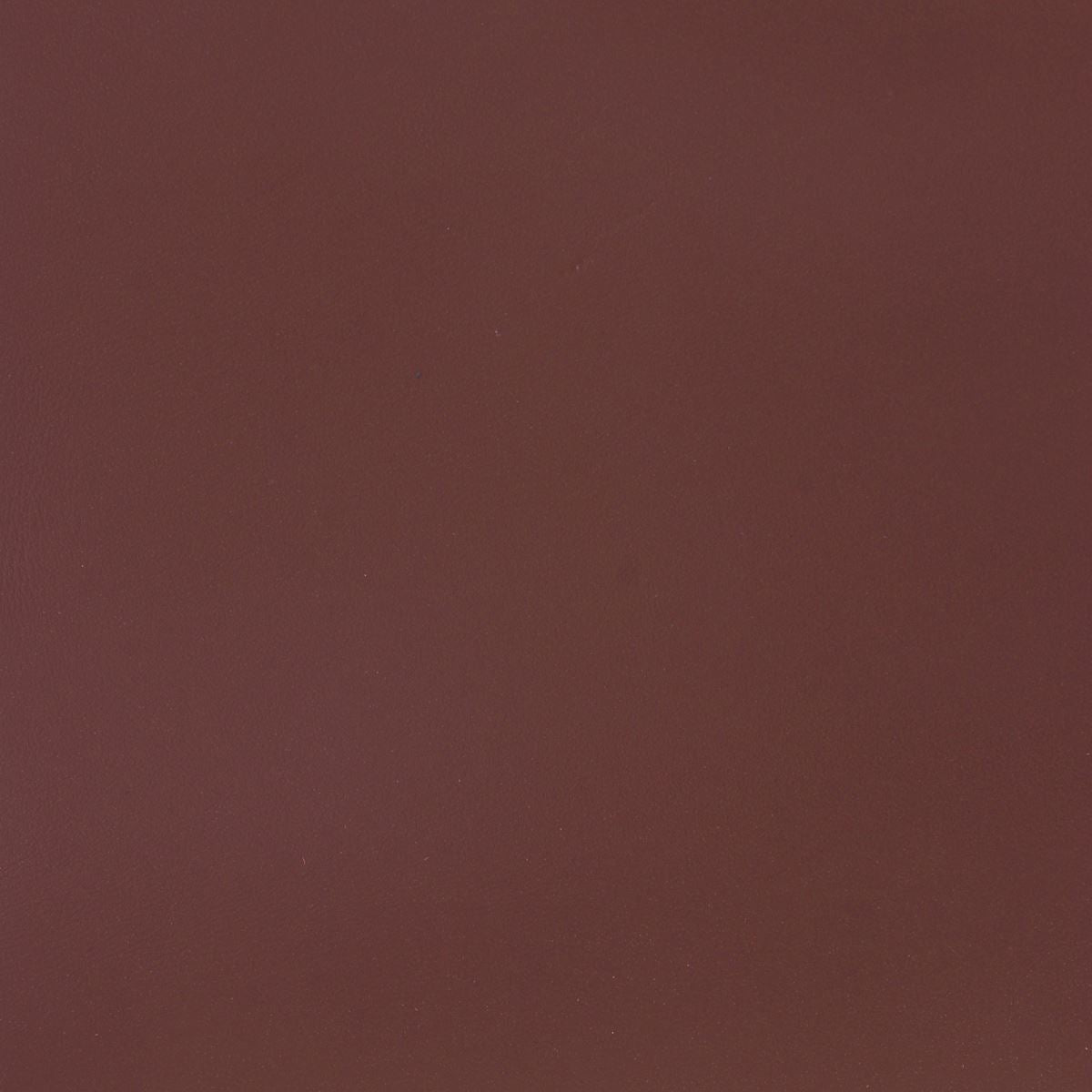

For the vegetable-tanned example, we chose 1 mm thick leather from the Sauvage range . Due to its thickness, we reserved it for part P1 (exterior). For all other parts, we opted for 0.5 mm thick natural vegetable-tanned leather.

THE NECESSARY EQUIPMENT

Mineral tanned version:

- 3 pieces of SATINLYS leather - CHESTNUT 20 x 30 cm - 0.5 mm thick

- 1 piece of SATINLYS leather - CHESTNUT 30 x 40 cm - 0.8 mm thick

- 1 piece of SATINLYS leather - CHESTNUT 15 x 20 cm - 0.8 mm thick

Cost: approximately €30.00

Vegetable tanned version:

- 4 pieces of natural vegetable-tanned leather , 20 x 30 cm - 0.5 mm thick

- 1 piece of wild vegetable-tanned leather, 20 x 30 cm - 1 mm thick

Cost: approximately €45.00

Hand-sewn version only:

- 2 cardboard pieces or 1 spool of MeiSi super fine waxed linen thread M40 - ⌀ 0.45 mm

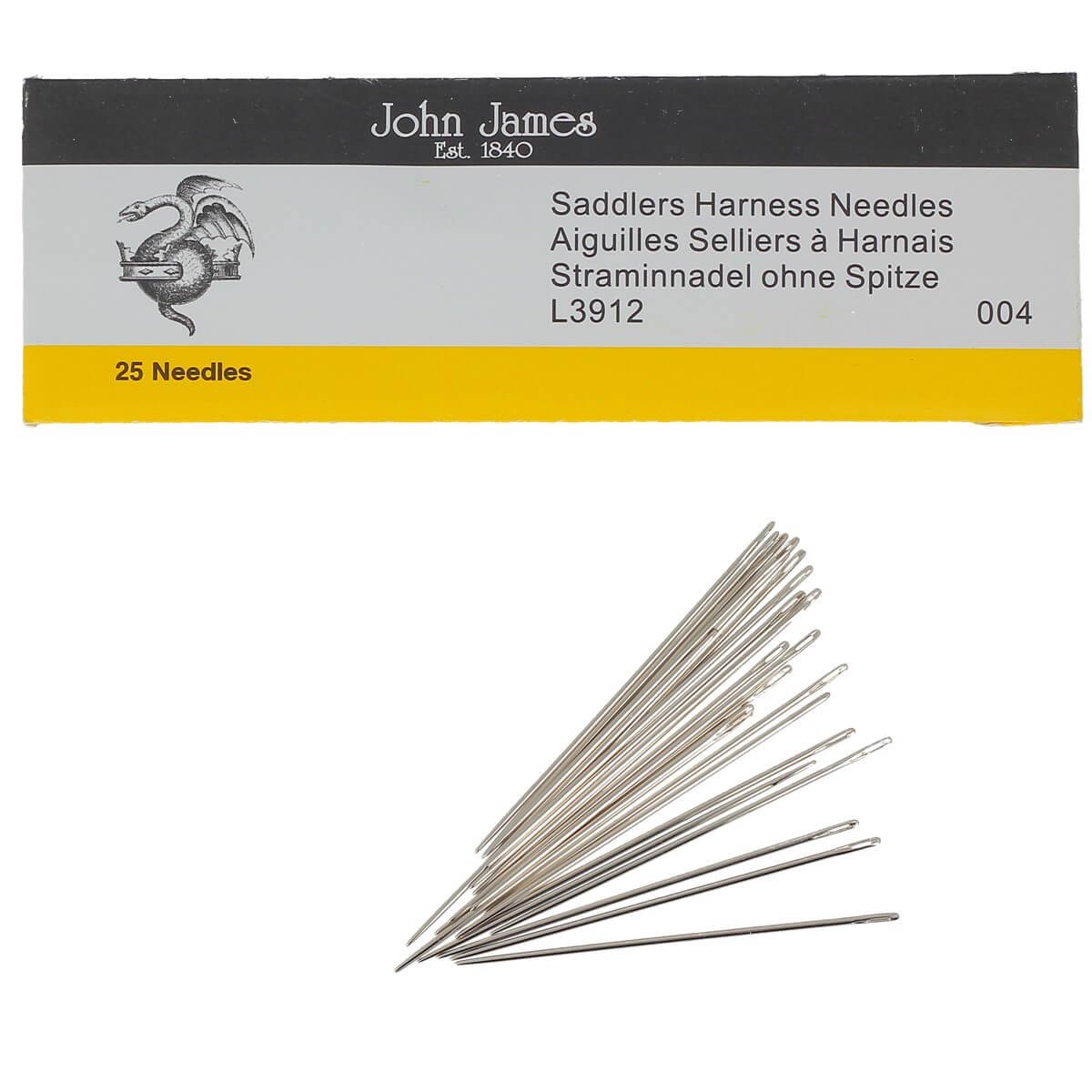

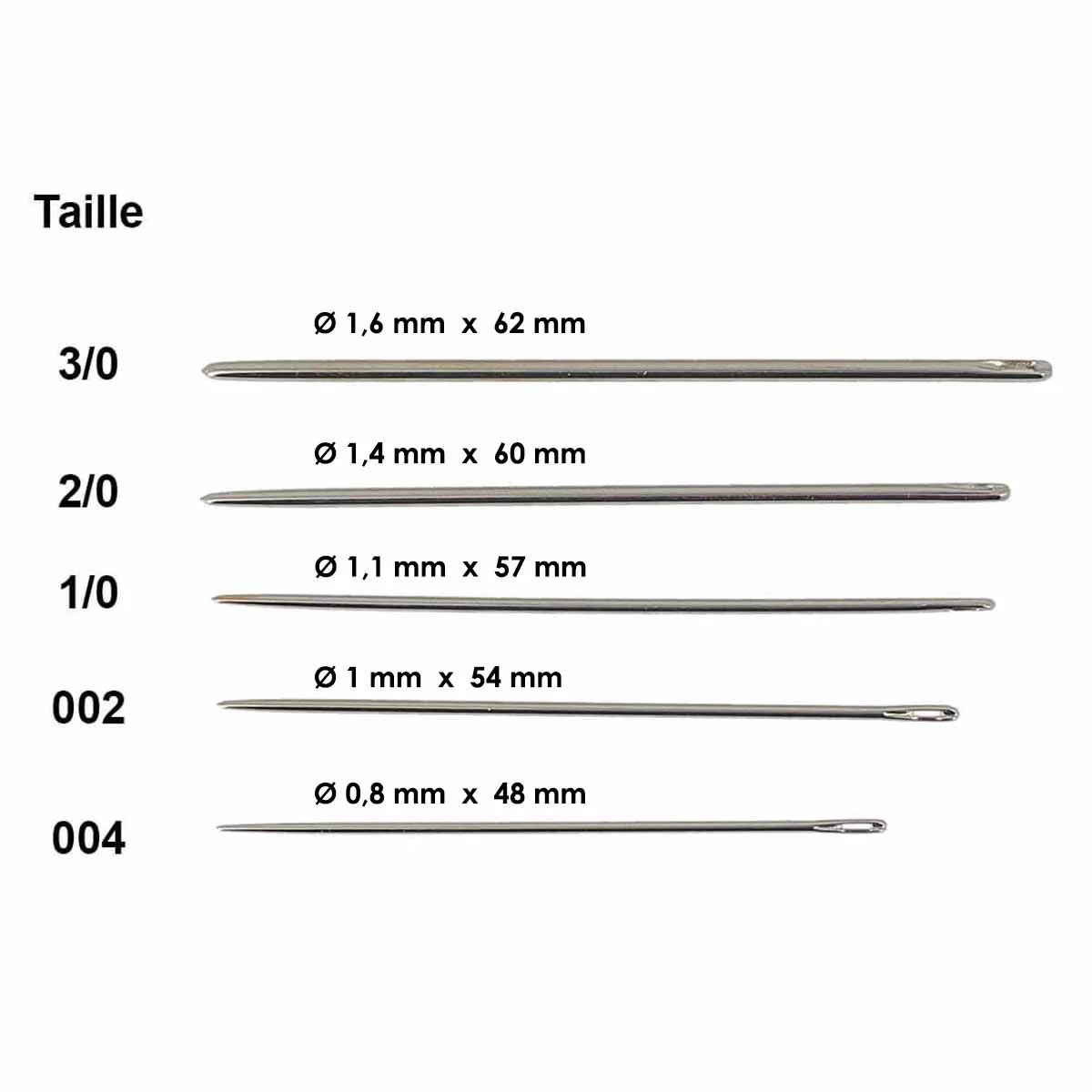

- 2 saddler's needles - Round tip - John James - ⌀ 0.80 mm (size 004)

- 1 dry-point compass

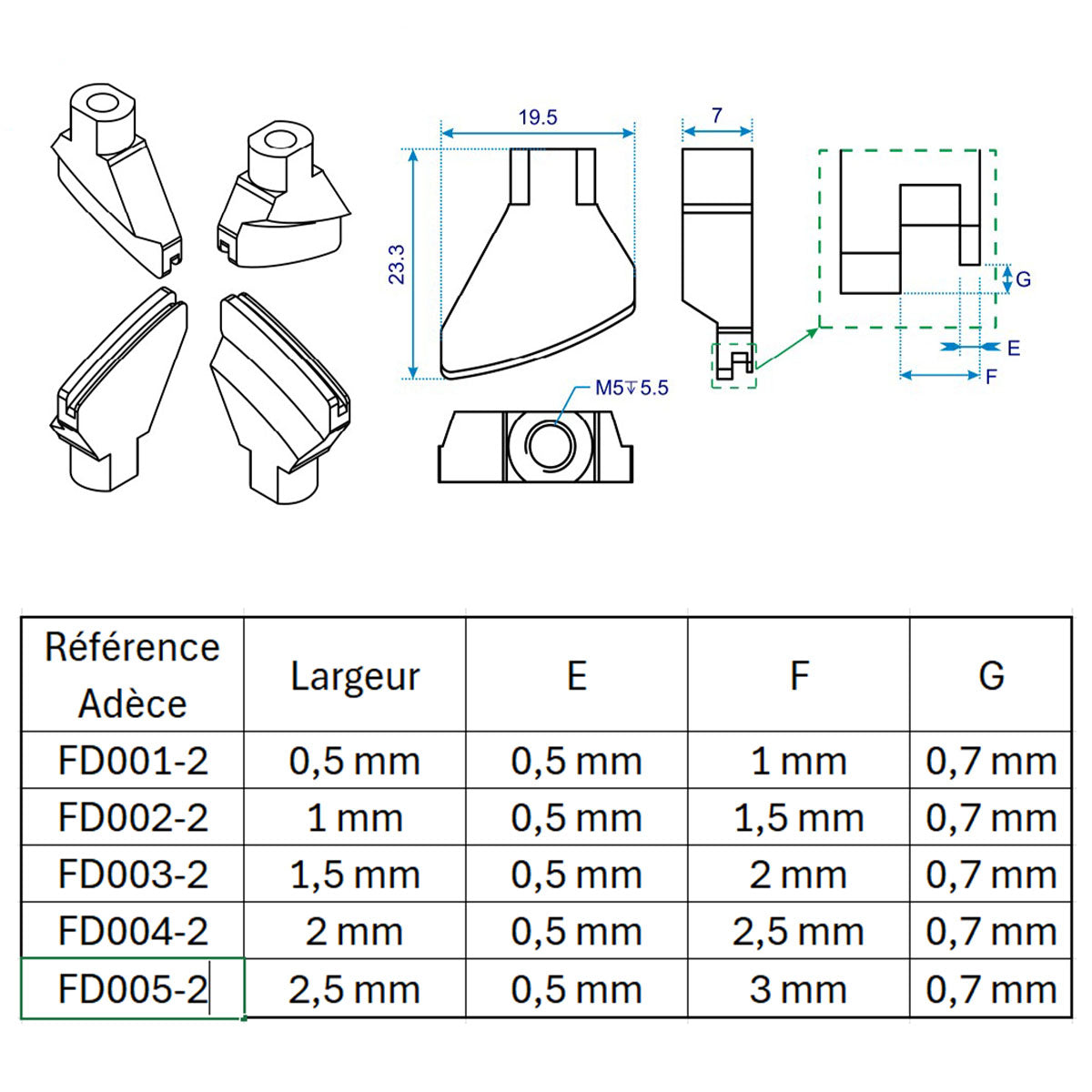

- Striking claws with 3.38 mm center distance

- 1 block of wax

- 1 saddler's clamp or a sewing valet

- 1 round awl

- 1 awl with pliers

- 1 joiner's hammer / riveting hammer

List of materials for all versions:

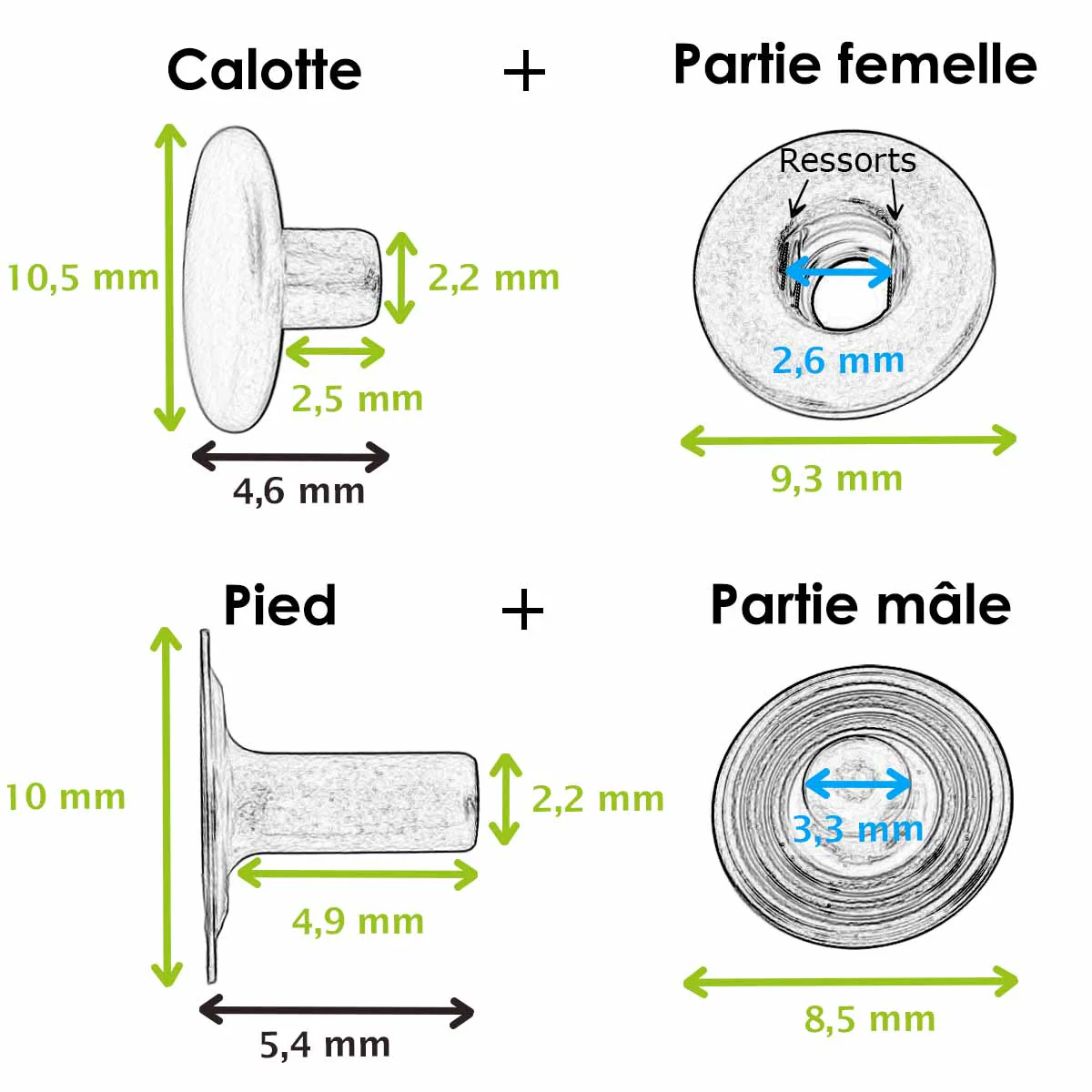

- 1 brass snap fastener - Ø 10.5 mm + its setting tool

- 1 precision leather rasp file - 4 mm

- 1 pot of neoprene glue

- 1 steel roller - Smooth wheel for pressing leather - Ivan

- 1 square lampshade - Leather Decor

- 1 cutter, 9 mm blade, 30° stainless steel

- For edge finishing: a pot of edge dye (if mineral tanning) or tokonole (if vegetable tanning).

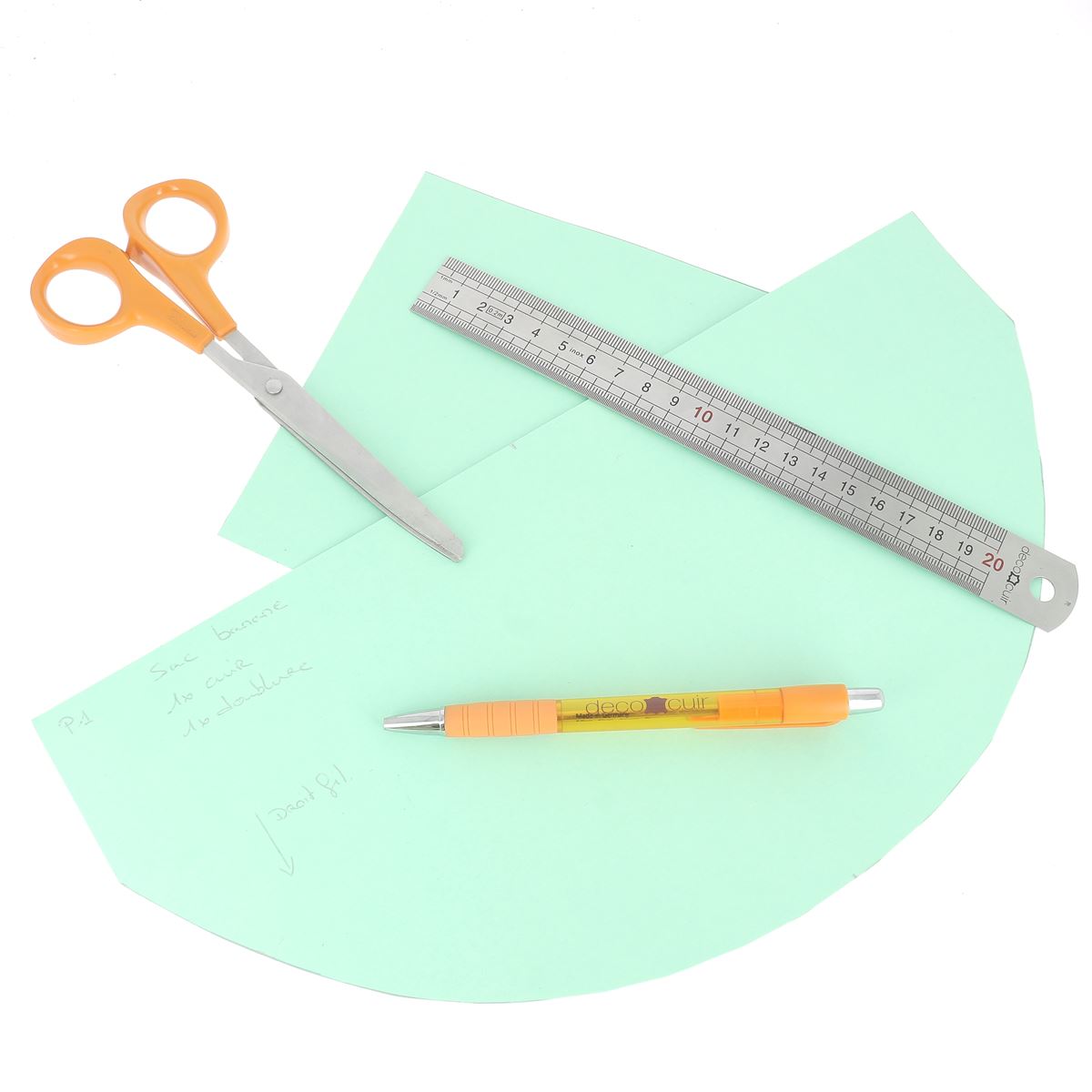

GET THE PATTERN

The wallet pattern is available for purchase on our website (reference KA210). It is only available in digital format: a PDF to print at actual size and assemble.

We recommend reproducing the pattern pieces onto pattern card.

FULL VIDEO TUTORIAL

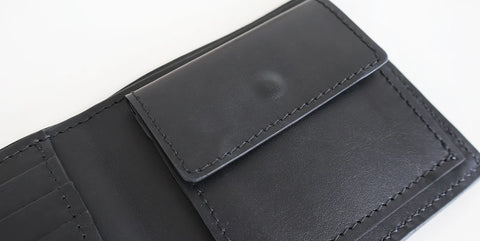

PART 1: THE CUTTING

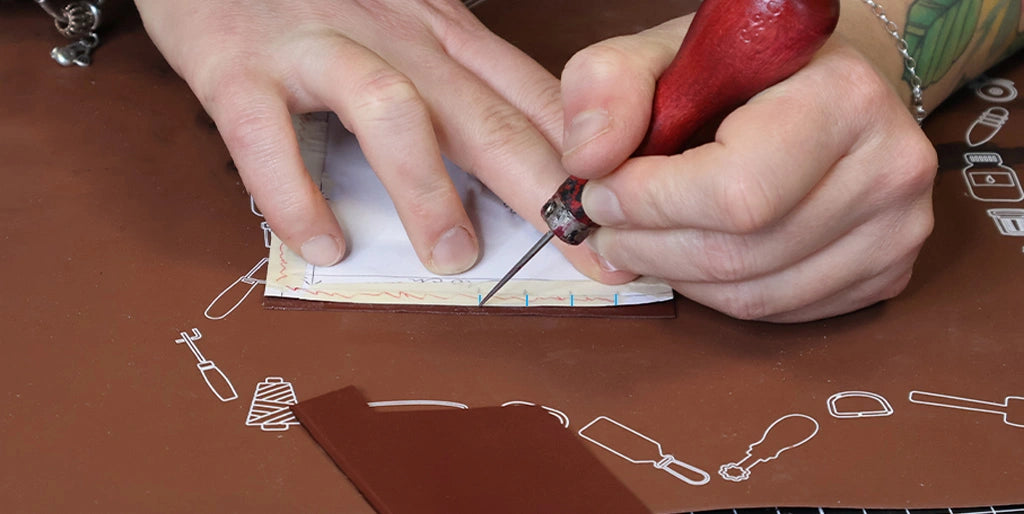

1. Cut out and trace the paper pattern

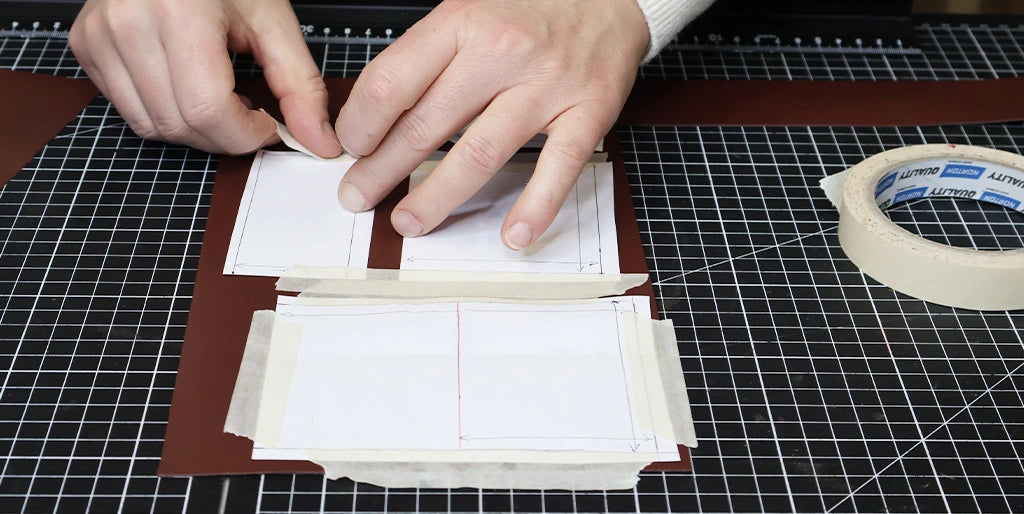

Cut out the pattern and then hold it, with masking tape or a weight, on the pieces of leather respecting the indicated thicknesses.

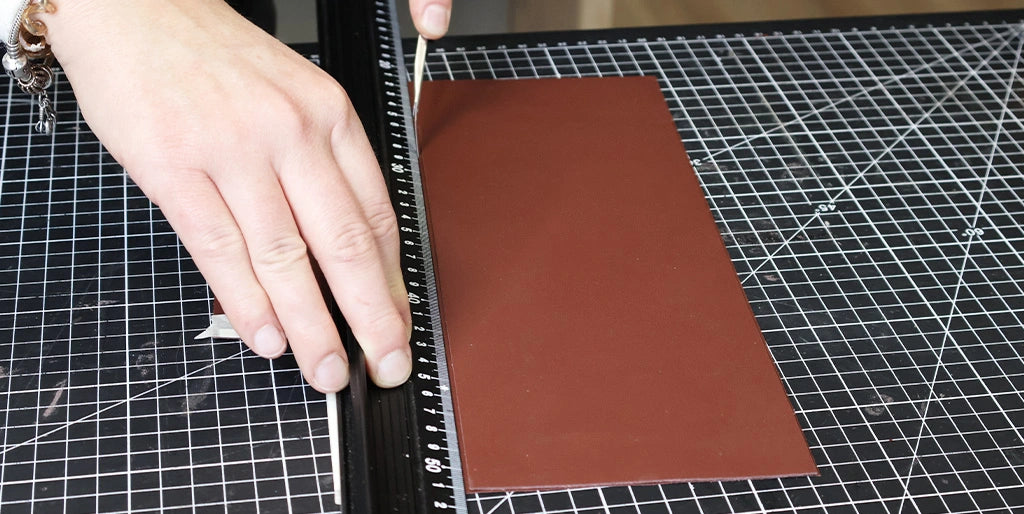

2. Cut out the pattern pieces

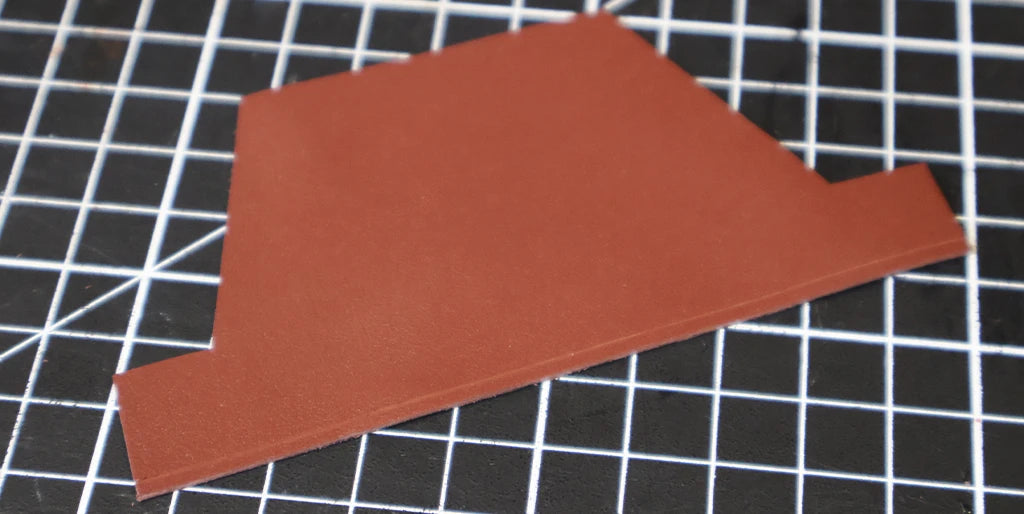

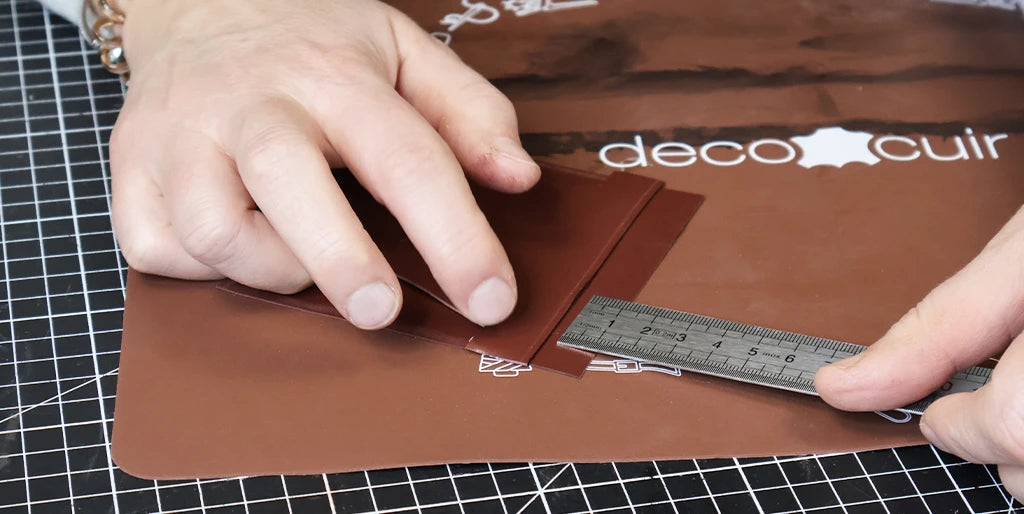

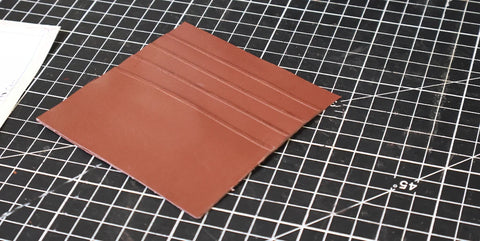

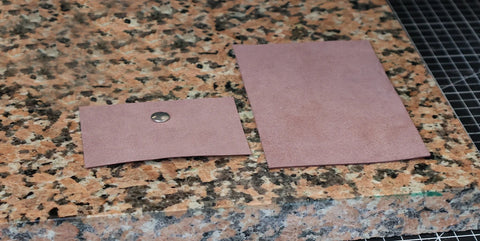

Cut out pieces P1 and P2 on the dotted lines of the pattern (cutting margins) before gluing them together and overcutting them.

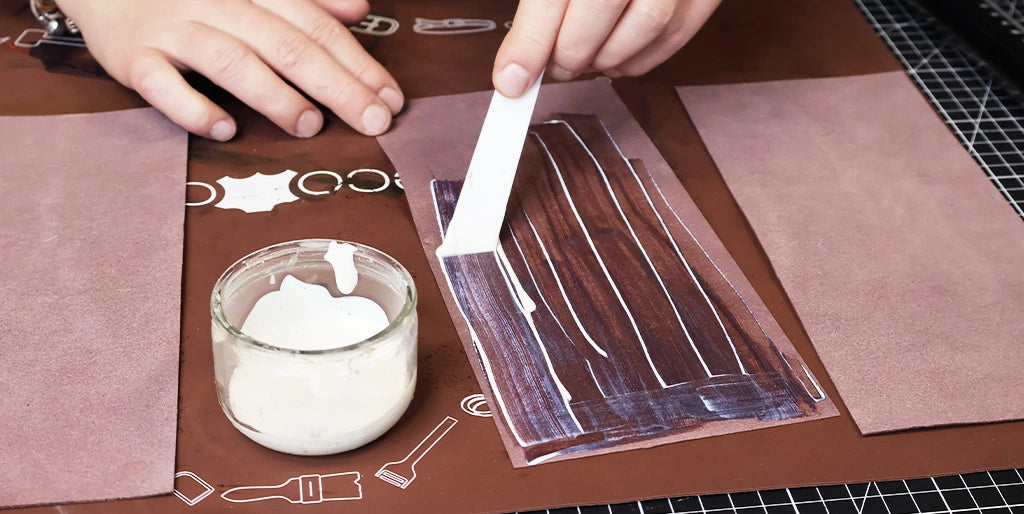

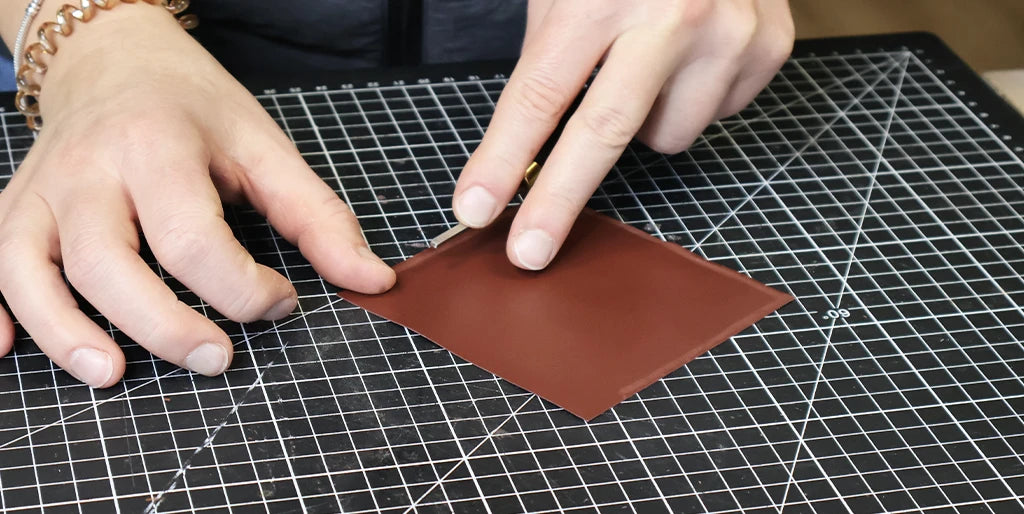

Next, glue the two P1 pieces together, wrong sides together, using contact glue (here neoprene) .

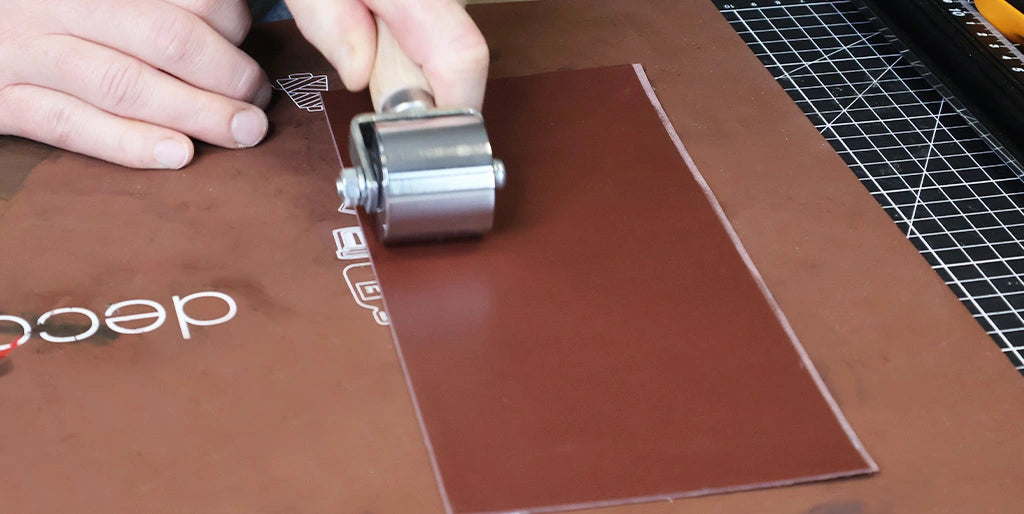

Press the leather to flatten the glued area.

Then cut out the pattern for piece P1 from this doubled rectangle.

Follow the same steps for parts P2.

For the other pieces : cut with a cutter following the lines of the pattern except for P4 and P7 (B) which must be cut on the dotted lines - cutting margins (these are lining pieces which will be recut).

For piece P2 (A ): transfer the four blue points from the pattern using a round awl. These marks will be used to know where to glue the pocket in the following steps.

For piece P7: use a round awl to lightly mark the locations of the blue lines on the pattern. These marks will allow you to correctly glue the card holder pockets (pieces P8).

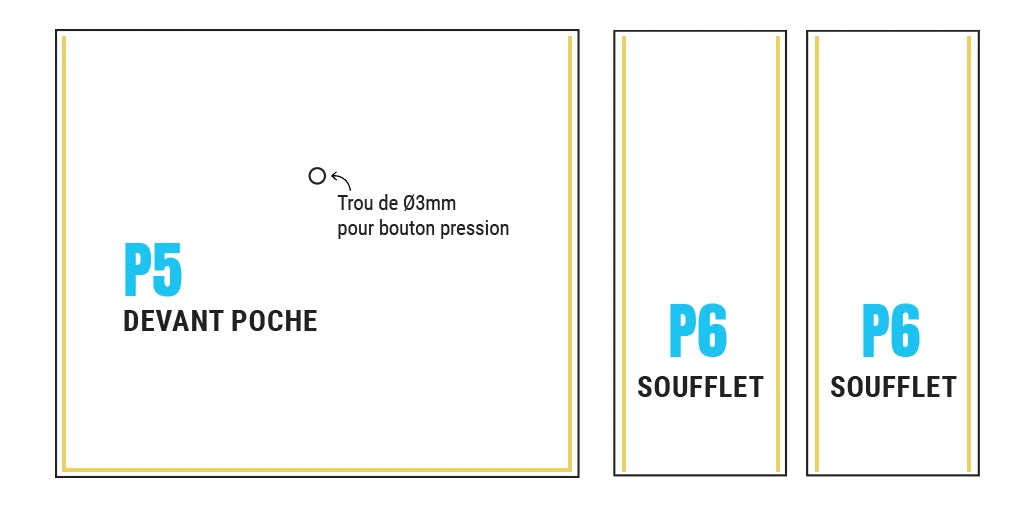

Note: Do not drill the Ø3 mm hole for the snap button immediately.

PART 2: THE CARD HOLDER

3. OPTION: Make decorative nets

Create decorative fillets on the top of pieces P8 and P9, 1.5 mm from the edge.

For mineral-tanned leather:

The fillet must be made while hot, using a filleting iron.

For vegetable-tanned leather:

The thread can be made cold with a thread cutter, a dry-point compass or a forming tool… or hot with a threading iron.

4. Work the slices

Work the top edges of pieces P8 and P9 (the length including the decorative fillet). Use an edge dye for mineral-tanned leathers and Tokonole for vegetable-tanned leathers.

SEE THE GUIDE TO THREADING IRON AND SLICING

5. Trim the corners

To avoid excess thickness at the card holder, we recommend slightly beveling the corners of parts P 8 and P9.

|

|

6. Assemble the card holder

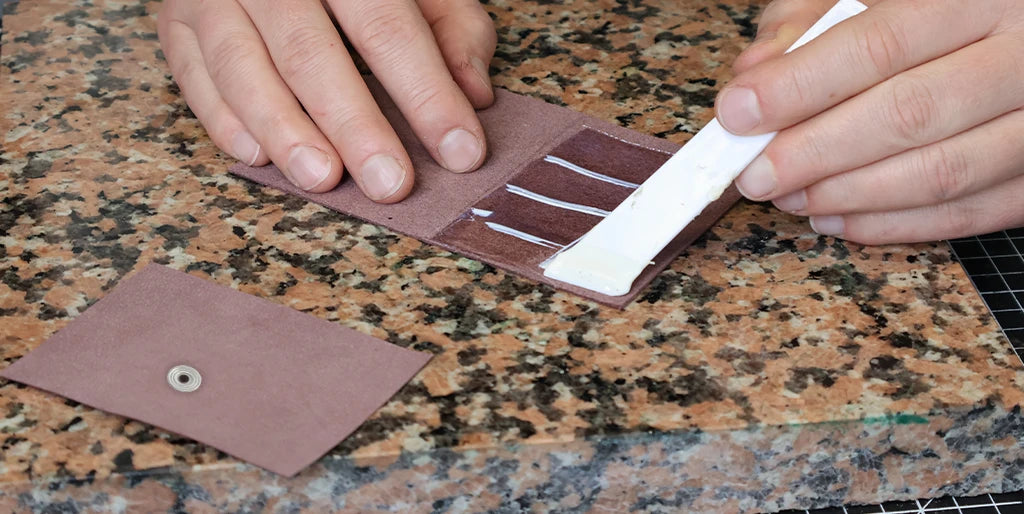

To improve adhesion, lightly scrape the grain side of the leather on piece P7(a), along the pink lines indicated on the pattern. Be careful not to scrape higher than the lines.

Glue the first piece P8 by applying glue to the bottom of the piece as well as to its two sides. Also apply contact adhesive to piece P7, 1.3 cm from the top.

See photo ⬇️

Glue piece P8 onto P7, making sure that it is 1.3 cm from the top of piece P7.

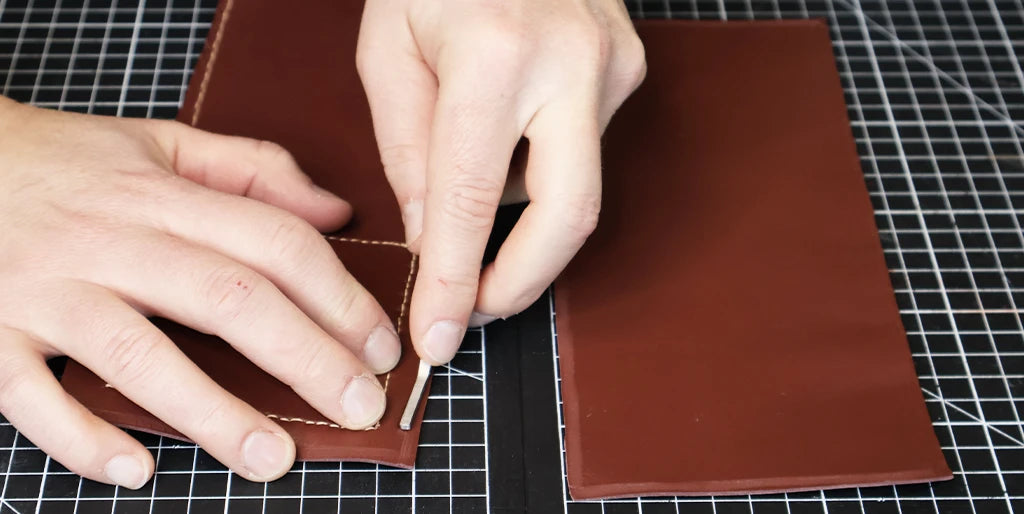

Sew the bottom of piece P8 onto P7. Two sewing options :

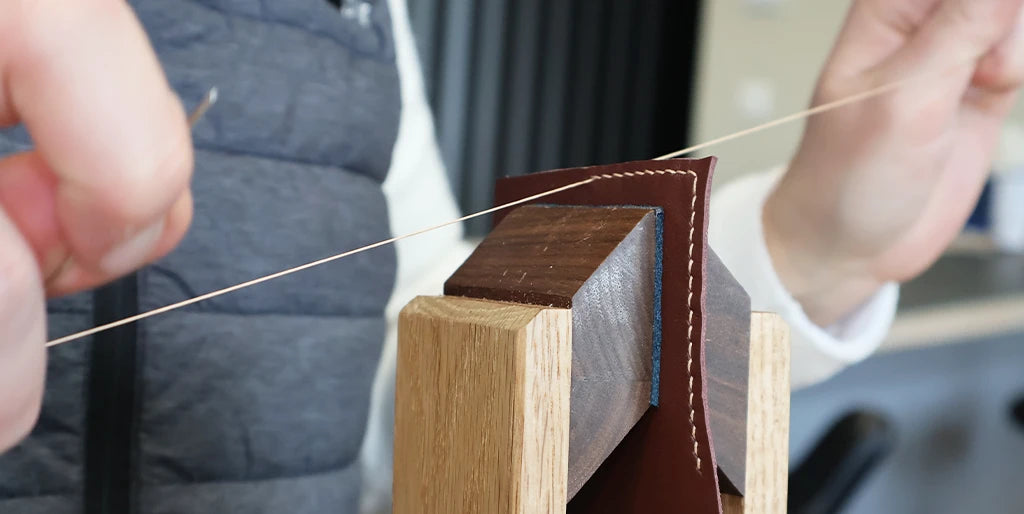

- Hand-sewn with saddle stitch

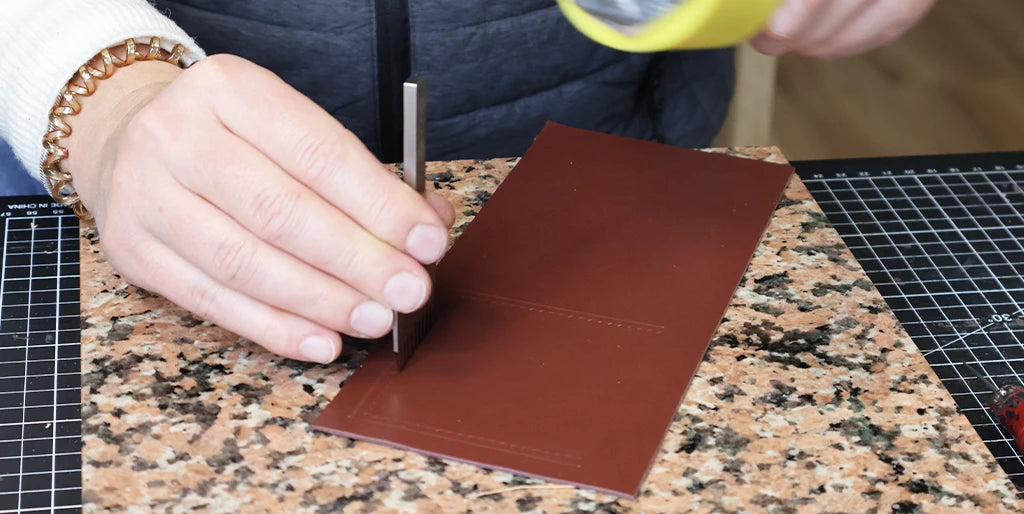

Using a dry-point compass, draw the seam line 3 mm from the bottom edge of piece P8.

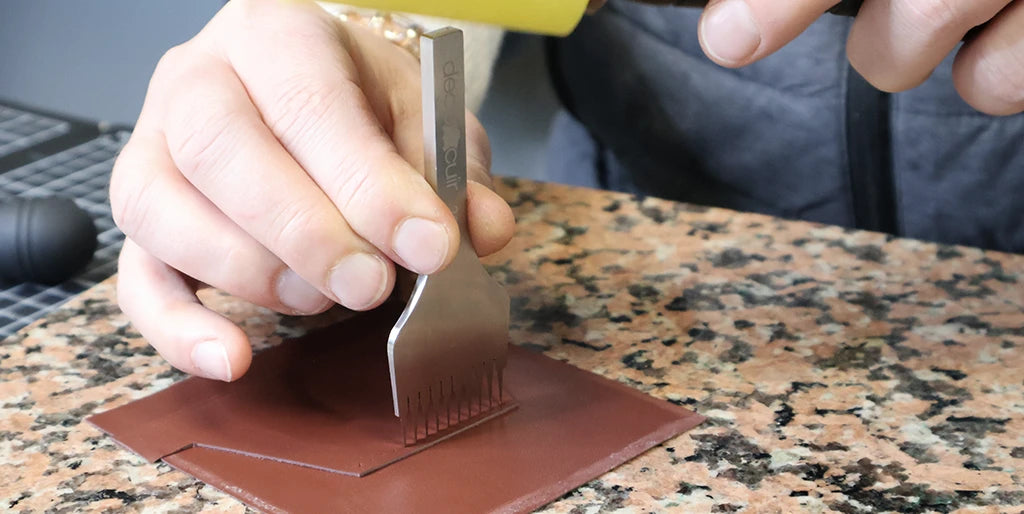

Mark the stitch points with a tack hook.

Sew using the saddle stitch.

SEE THE SADDLE STITCH SEWING GUIDE

- Sewing machine

To save time, it is possible to sew this part with a sewing machine.

Do the same with the other two P8 pieces.

Glue piece P9 onto the bottom of piece P7.

|

|

7. Glue and sew the right side of the card holder

Once all the parts are glued, take the second piece P7(b). Glue the two pieces P7 together, back to back, using contact adhesive.

|

|

Overcut.

Sew the right side of the card holder (by hand or machine) .

You only need to sew the right side because the other three sides will be sewn later, during the final assembly of the wallet.

If hand-sewn:

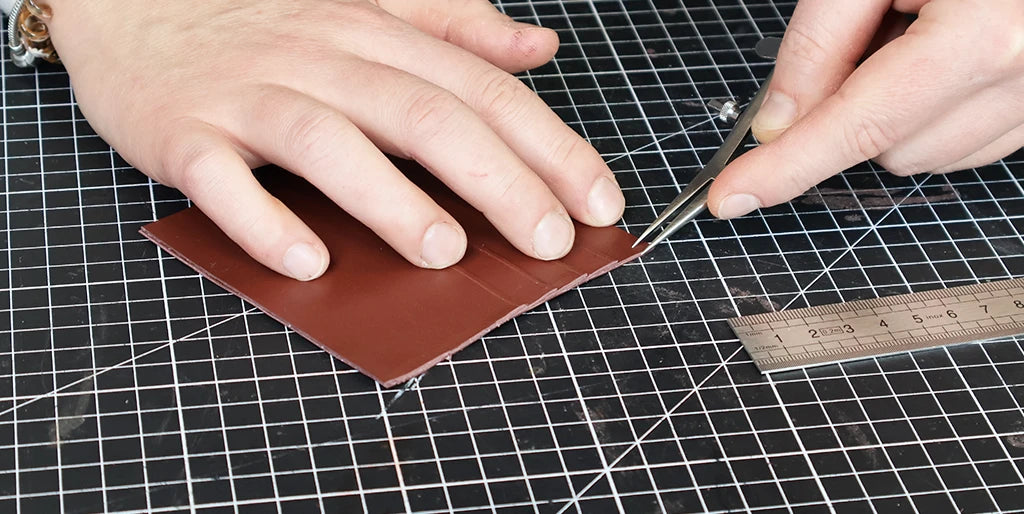

Using a dry-point compass, draw a line 3 mm from the edge on the right side of the piece.

Mark the stitch points with a tack hook.

IMPORTANT : To avoid weakening the sides of the card holder, be careful not to sew over the gaps. We recommend using a two-pronged awl and offsetting the stitches if necessary to properly position them between the different pockets of the card holder.

Sew using the saddle stitch.

|

|

8. Work the slice

Work on the edge that has just been sewn. Overcut if necessary, sand and apply an edge finish.

|

|

9. Grate the back side

Turn the card holder over and smooth down the three remaining sides on the back of the card holder. This will make it easier to glue onto part P2 in the following steps.

PART 3: THE WALLET

For those who never carry change, it is possible to make another side a card holder rather than a coin pocket.

10. Attach the Ø10.5 mm snap fastener

There are 2 possibilities for attaching the snap fastener:

|

OPTION 1: COVERED BUTTON

|

OPTION 2: HIDDEN BUTTON

|

|

|

Option 1: Sheathed button

For a discreet and refined snap button, it is possible to cover it with the same leather as that used for the wallet.

Here are the steps to follow:

1. Begin by gluing the lining P4 to the designated location on piece P3, wrong sides together. And overcut.

|

|

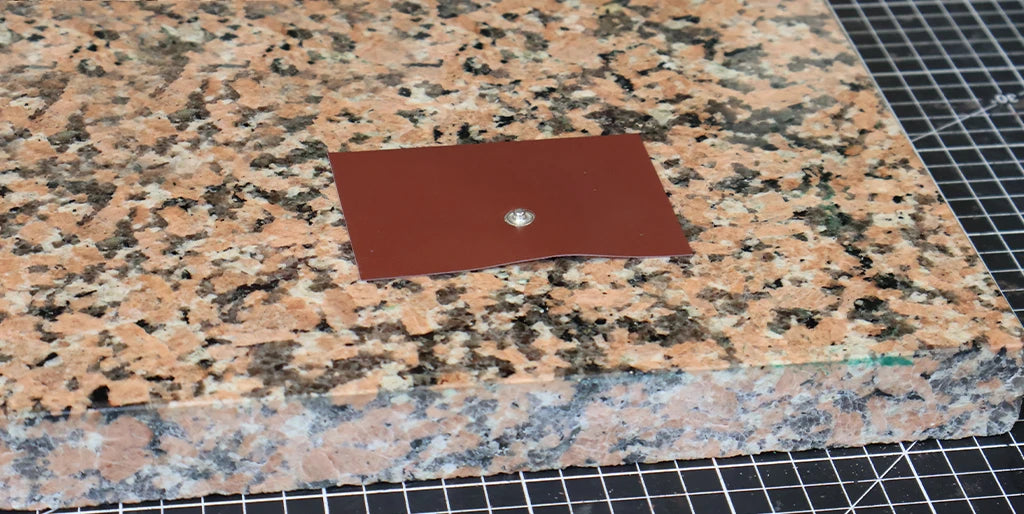

2. Drill the Ø 3 mm holes on parts P3/P4 as well as on part P5.

3. Place the base of the snap fastener onto part P5.

4. Cut out a small square of leather measuring 5 x 5 cm, with a maximum thickness of 0.5 mm. Apply contact adhesive to the back of this square.

5. Allow the glue to dry for a few moments, then lightly sand the head of the snap fastener to improve adhesion.

6. Place the head of the snap fastener in the center of the leather square, then fold the leather towards the inside of the snap fastener.

|

|

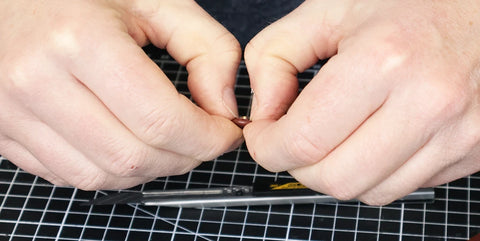

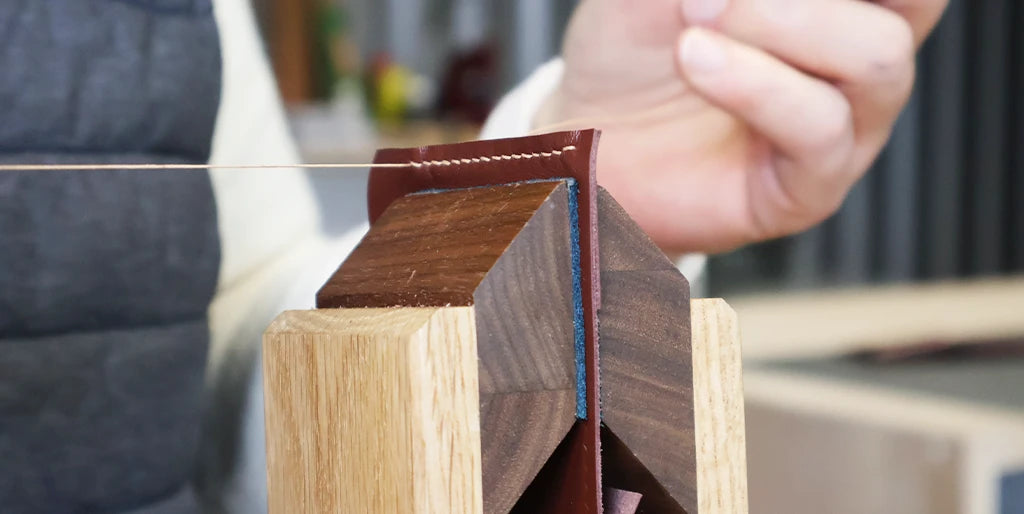

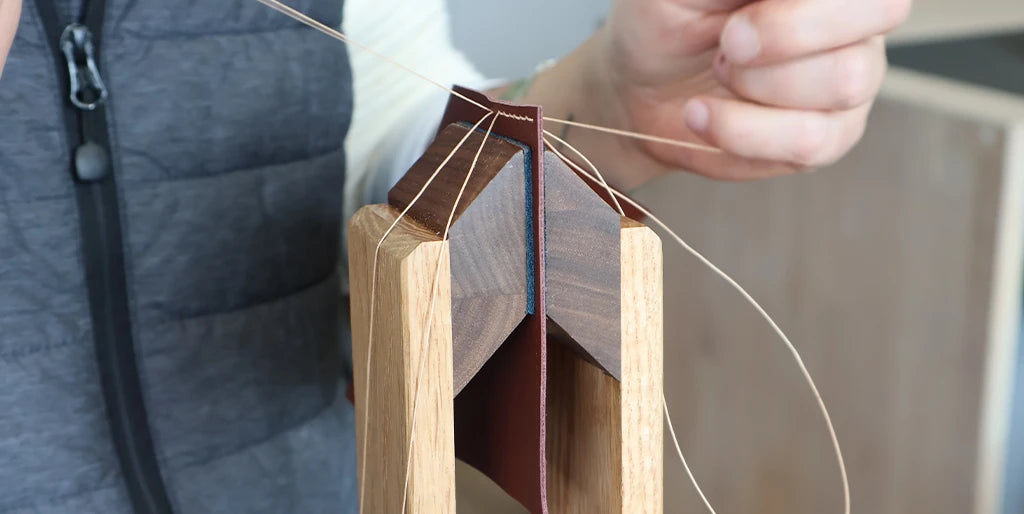

7. Using thread, make several turns around the shank of the snap fastener to stretch the leather towards the inside of the snap fastener. Pull very tight and tie a knot.

Allow the glue to dry for several hours (or even a whole day) to ensure a good bond.

|

|

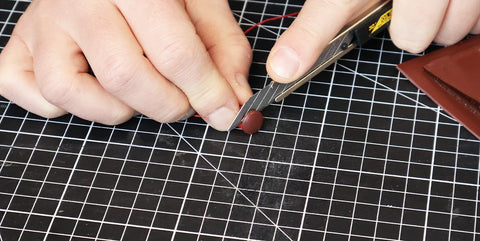

8. Once the glue is dry, use a craft knife to trim the excess leather around the head of the snap fastener . Using your fingernails, gently fold the edges of the leather inside the snap fastener.

|

|

9. Place the snap fastener in the designated location on part P3/P4.

|

|

Option 2: hidden button

For an invisible snap fastener, it can be hidden in the lining at the top of the pocket. Here are the steps to follow:

1. Start by drilling the Ø 3 mm holes for the snap fastener only on parts P4 and P5. Do not take into account the hole on part P3.

2. Place the head of the snap fastener on piece P5 (front of pocket), with the domed part on the underside of the leather.

|

|

3. Then, place the foot of the snap fastener on piece P4 only (flap lining).

11. Sew the lining of the flap

If you opted for the hidden snap button in the lining (option #2): glue the lining P4 to the designated spot on P3, wrong sides together. And overcut.

Using a dry-point compass, draw the seam line 3 mm from the edge on the top width and on both lengths of piece P3, up to the lining stop.

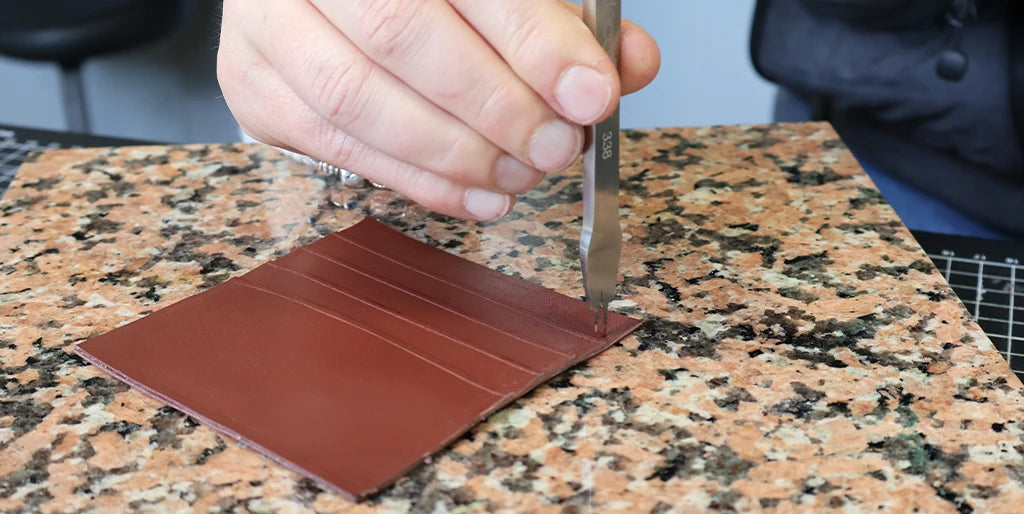

Mark the stitching points with a spiked awl, across the top width and both lengths of piece P3, up to the lining stop.

Reminder: always start by working on the angles with a two-pronged awl: the rule is that the point located in the angle should always point towards the center of the piece. It is also possible to mark the angle with a round awl.

Sew these three lengths together.

Next, sew the remaining line of the lining. Trace the line and mark the stitching points directly onto the lining.

|

|

Strike the seams using a joiner's hammer or a riveting hammer.

12. Round off the corners

Using a cutter, break off the top corners of P3/P4.

Next, sand the edges with an abrasive sponge.

13. Grate the back of the pocket

Using a rasp, sand the remaining lines (those not sewn) on the right side of piece P3.

|

|

14. Sew the rest of the pocket

Using a dry-point compass, draw the stitching lines 3 mm from the edge of pieces P5 and P6.

Diagram of the lines where to draw the seam:

Mark the stitching points on these same lines.

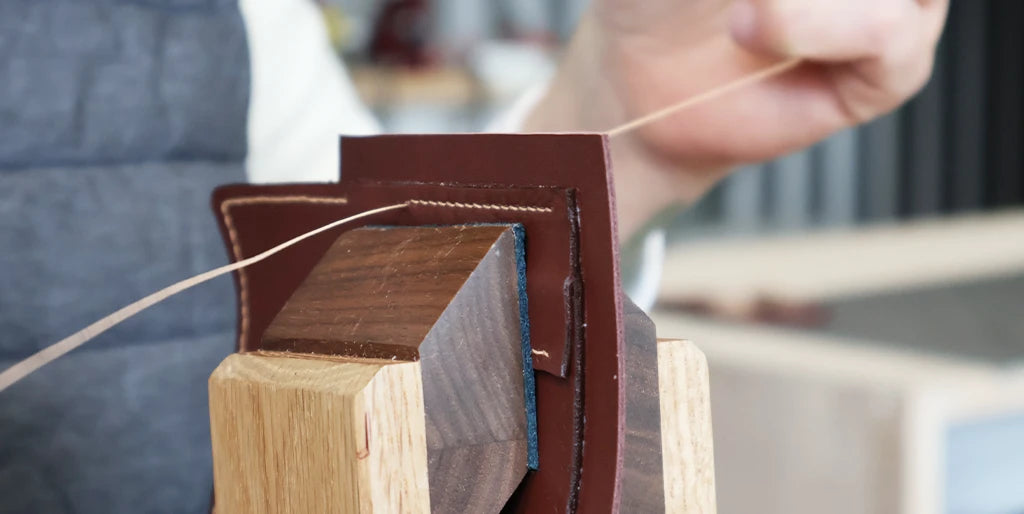

Here, we will use a double slash stitch to sew the gussets onto piece P5. This will ensure a neat stitch on both sides of the leather (given the thinness to be joined).

Note that for double scoring, slightly enlarge the holes with a round awl, not with pliers. Be careful not to insert the round awl too deeply to avoid cracking the holes previously made with the claws.

Glue the P6 bellows to the sides of P5, 3 mm from the edge. Wrong side to wrong side.

|

|

Then, sew these two lines together.

15. Working the slices

Sand and apply edge stain or Tokonole to all edges of parts P5 and P6.

16. Glue the front of the pocket to the back of the pocket

Once the edges of the front pocket are dry, apply contact adhesive to 3 mm of the unlined sides of piece P3 (on the reverse side of the leather/flesh side) . And on the unsewn lengths of the gussets P6.

|

|

Glue the front of pocket P5+P6 onto P3 and tap the glued area with a taping hammer. To properly form the gussets, fold them before gluing. Refer to the photos below.

|

|

17. Working with the slices

Work the slices all around the pocket.

If this has not been done, make a decorative net on the front of the pocket (optional).

PART 4: THE INTERIOR

18. Prepare part P2(a)

Using a compass with a 3 mm center distance, draw the lines of the pocket location on piece P2 (a), indicated on the pattern.

On the inner line, mark the stitching points with a tack hook.

Then grate that area.

19. Glue the pocket onto P2

Apply a thin bead of contact adhesive to this same area. Also apply adhesive to the scraped areas on the back of part P3.

|

|

Glue the pocket onto piece P2(a) following the outer line drawn with a compass.

20. Sew the pocket

Sew the remaining lengths of the two gussets using a double hook stitch (use the round awl) .

Then, sew the bottom line, making sure to catch the gussets in the seam.

21. Glue the card holder

Grate piece P2(a) where the card holder will be glued (see the pink hatched lines on the pattern).

Then, apply contact glue to these three sides and to the three unsewn sides of the card holder (in the area that was scraped in step #9).

Glue the card holder onto part P2. Flatten the glued area with a joiner's hammer.

|

|

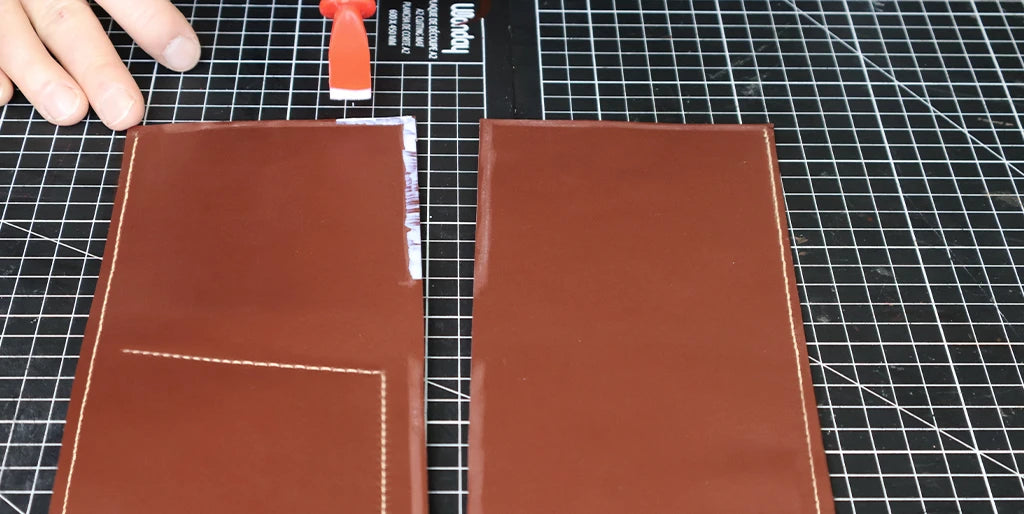

22. Draw the sewing lines

Draw a line 3 mm from the edge all around piece P2, the card holder, and the pocket. Be careful not to draw the stitching line over the area not to be sewn (the middle area).

|

|

Caution : as in step 7, care must be taken to ensure that the stitching points fall at intervals at the edges of the card holders: use a 2-pronged awl.

23. Option: Make the decorative net

For a professional finish: create a decorative border all around the room.

24. Sew the top line of piece P2

For now, only sew the top line of piece P2.

25. Grate the back of P2

To facilitate gluing with part P1, rasp the 3 remaining sides on part P2(b).

PART 5: THE EXTERIOR

26. Sew the main piece

Take piece P1 (large outer piece). With a dry-point compass, draw the seam line 3 mm from the edge all around piece P1, except at the "Area not to be sewn" indicated on the pattern.

Using marking clips, mark the stitching points all around piece P1, following the stitching line (except on the area not to be sewn).

Create a decorative fillet 1.5 mm from the edge all around piece P1.

Vegetable tanned version : bevel the edges all around piece P1.

Sew only the top length of piece P1.

27. Work the slice

Work the edge of the length that has just been sewn. Sand, then apply an edge dye or tokonole depending on the leather chosen.

28. Grate the leather

Using a rasp, lightly score the leather (inside, the lining) in the areas that will be glued later. That is: the two widths, then the length of the bottom of piece P1, except for the area not to be sewn.

|

|

PART 6: FINAL SEWING

29. Glue pieces P1 and P2 together

Apply contact adhesive to the areas that have been sanded on part P1 and on part P2(b). Be careful not to apply adhesive to the area that should not be sewn.

Glue the two pieces together.

|

|

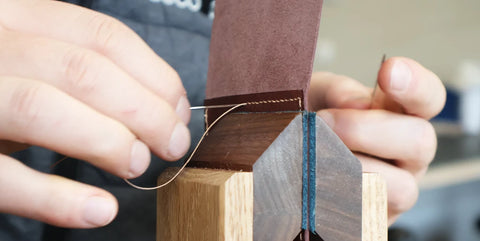

30. Sew pieces P1 and P2

The leather is already scratched on each side, all that's left is to sew it.

Hand-sewn version : Note that you must use the double-ripping method (for a neat seam) : pierce the leather on both sides (with the same prongs) and then pierce the stitching points with a round awl (using a diamond awl will create cross stitches) . Be careful not to sew the area indicated on the pattern.

|

|

31. Final touches

Using a crease tool or crease roller, crease the fold of the wallet to make it easier to close. Also crease the card holder pockets to soften them, making it easier to insert cards.

Strike the fold with a riveting hammer. Protect the leather with a cloth.

Slightly break the four corners with a cutter. Then, sand to form a nice rounded shape.

|

|

Work with the remaining slices.

Customization

You have the option to personalize your wallet with initials, a word, a logo... with hot stamping (vegetable and mineral tanning) or cold stamping (vegetable tanning only).

Well done, you've finished!