WHAT IS LEATHER REPUSHING?

Embossing is the highlighting of a pattern on vegetable tanned leather. To carry out this relief and thus highlight your design, the leather is pushed back with various stamps. Pushing therefore consists of crushing the leather fibers around the lines of your pattern.

How to repel leather?

We invite you to watch our 7 videos which explain the work of leather re-pushing step by step. Don't forget to download the template (the floral pattern) at the top of the page.

| PART 1: Leather embossing: transfer of the design. | PART 2: Re-pushing the leather: cutting with a swivel knife (opening knife). |

| PART 3: Re-pushing leather with bevelers. | PART 4: Leather Reembossing with Thumbprints Stamps - Shading work. |

| PART 5: Reembossing the leather with camouflage, veiner and lifter stamps - Raising work. | PART 6: Leather embossing with the backgrounder stamp and decorative cutting - Background work. |

Which leather to choose for leather embossing?

Natural vegetable tanned leather is the most suitable leather for leather embossing. We advise you to opt for the PREMIUM range of vegetable-tanned collar leathers (thickness 2.5 mm - 3.3 mm and 3.8 mm). PREMIUM leather is softer and thicker than CLASSIC leather: this makes the work of embossing easier and will allow you to better showcase your creation.

What tools for leather re-pushing?

- The modeler/plotter allows you to transfer the design onto the leather (with a tracing sheet).

- The opening knife, also called a swivel knife, allows you to incise the leather to give relief to your pattern. The index finger is positioned on the stirrup, the thumb and middle finger on each side of the handle as if holding a pencil. The index finger controls the depth of the cut while the other fingers are used to rotate the tool to make the desired shapes.

- The beveler stamps allow you to give relief to the design by hammering them on the contours (cutting). The Beveler 6197 - 6203 -6935 stamps are essential for much of the leather embossing work.

- The Barry King Tool maul / mallet has a perfect balance between the handle and the head which allows ease of use. Pay attention to the striking force which must be regular.

- The marble will give excellent inertia to your mallet blows when pushing back your leather (it will absorb vibrations).

- Without forgetting Easy-Carve or Pro-Carv : professional product for leather before spinning (to be diluted with water). The leather absolutely must be moistened to be able to push it back.

The dictionary of stamps

We have listed for you our range of more than 400 stamps for leather embossing. Discover the function of each family of stamps on handles and find a pattern, a shape, a dimension more easily thanks to our stamp dictionary!

LEATHER DECORATIVE TOOL KITS

We have drawn on our experience to offer you the essential tools for leather refinishing in starter kits.

How to choose your swivel knife blade?

The 7/32 attachment blades are compatible with all open knives from the Oka, Tandy Leather and Ivan brands. The 1/4 attachment blades are only compatible with Barry King Tools brand opening knives. Original blades are generally straight and flat. For a better grip we recommend curved blades. Beveled blades are generally used for small lines (finer cuts).

What is embossing?

Embossing consists of transferring an existing pattern to the leather by pressure. As with embossing, only natural vegetable tanned leather allows this cold technique to be implemented. For all other types of leather, it will be necessary to resort to hot embossing which requires industrial heating presses.

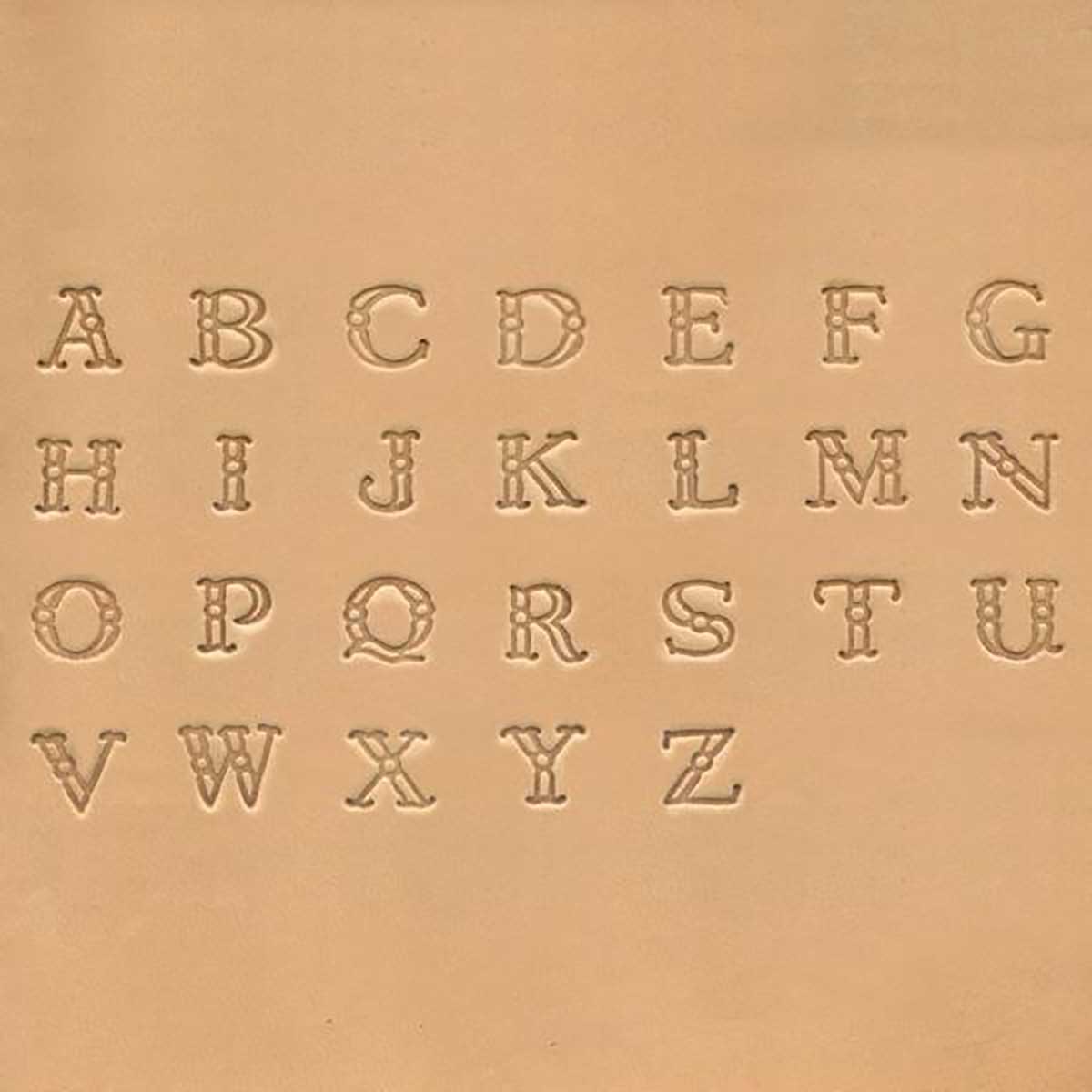

Marking is done using a generally metallic tool. There are numerous 2D and 3D stamp stamps offering a multitude of patterns such as animals, flowers, Celtic symbols, etc. The alphabet and number stamp sets also work using the embossing technique. To transfer the pattern to the leather, you must attach a stamp to a handle that you hit with a mallet (or use an embossing wheel). It must have a weight adapted to the size of your stamp. Indeed, large patterns require much more pressure to properly mark the leather. The mallet is usually made of wood or polymer. We do not recommend the use of a metal hammer which, with use, will damage your stamp.

The advantage of this technique is the saving of time and the quality of the pattern which is directly linked to the quality of the stamp used.

EXPLANATION OF BASKETWEAVE TECHNIQUE

The Basketweave (X) handle stamps take their name from the pattern created which resembles a woven basket. They allow you to quickly reproduce the same pattern in order to give a material effect and avoid keeping a large smooth surface.

To begin the embossing work, moisten the leather with a mixture of water and easy carve. Then draw (with a plotter) a reference line using 2 points on its creation.

Position the stamp on the handle (for our example: Basketweave fagot bias 11mm - X510) as close as possible to an edge. Then, strike the hammer on each side of the line. Be careful to tilt it at the edges so as not to exceed the decorative line. Have a maul heavy enough not to have to tap twice.

To learn the Basketweave technique, watch the video between minutes 12:35 and 19:03.

See the free “Knife sheath” tutorial >

Where to have your custom leather stamp made?

Would you like to have a personalized stamp with the name of your brand or a particular pattern? We advise you to contact specialized companies in particular: BFM - Leather tools and machines.

BFM will design your tool for cold or hot engraving/marking of leather.

Where to learn how to push leather?

For a weekend, come and learn floral leather embossing with Yves Lesire: training aimed at all levels!

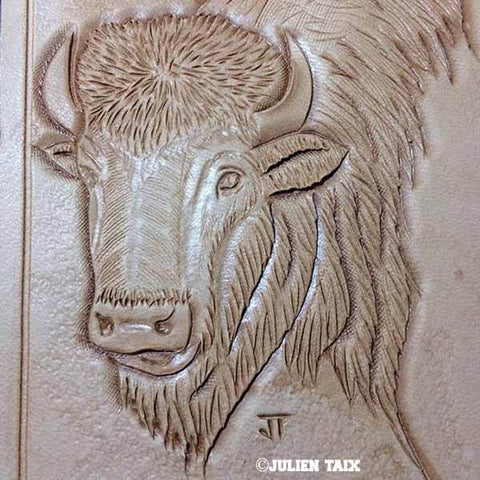

OUR CUSTOMERS HAVE TALENT

|

|

|

| ©L’Atelier d’Arcs Brassard val | ©Nordikha | ©Roseanne Laniece |

|

|

|

| ©Alain Mangano | ©Alain Mangano | ©Alain Mangano |

|

|

|

| ©Donatien Cebron | ©Alain Coquéro | ©Damien Coquelet |

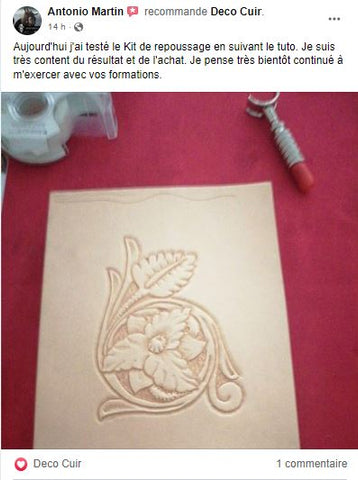

YOUR ACHIEVEMENTS

4 comments

DECO CUIR

Bonjour MGO,

Nous vous conseillons de commencer par le repoussage, puis d’appliquer votre teinture. La patine “Fiebing’s Antique Leather Stain” est généralement utilisée comme finition après la teinture. Pour finir, vous pouvez appliquer le Pro resist. N’hésitez pas à consulter notre guide complet sur les teintures et finitions : https://www.decocuir.com/blogs/blog-tutoriel-patron-cuir/comment-teinter-cuir-teinture .

L’équipe Deco Cuir

MGO

Bonjour,

Dans le cas de repoussage avec utilisation d’Antique Leather stain et Pro resist, si l’on veut que le cuir soit teinté, quel est l’ordre logique ?

D’abord la teinture puis repoussage ou tout le process de repoussage et teinture en dernier lieu ? dans ce cas j’ai peur que le teinte ne prenne pas apres le pro resist ?

Merci

Anonymous

Bonjour Aurélie,

Le choix de l’épaisseur doit se faire en fonction de ce que vous souhaitez confectionner : porte-cartes, manchettes, selles… Effectivement, pour rendre le travail de repoussage plus facile et vous permettre de mieux mettre en valeur votre création nous conseillons de choisir un cuir PREMIUM de 2,5 mm pour le repoussage du cuir : le cuir PREMIUM est plus épais et plus tendre que le cuir CLASSIC. https://www.decocuir.com/morceau-cuir-tannage-vegetal-c102x2677112

L’équipe Deco Cuir

Anonymous

Bonjour

Quelle épaisseur minimale conseillez-vous pour le repoussage du cuir ?

Des cuirs proposés en lien, je suppose que c’est 2.5 mm ?